This was our Holiday celebration meeting where everyone brought in something to eat and we had extra time to hang out and chat. We held a truncated business meeting, short wood auction and show & tell.

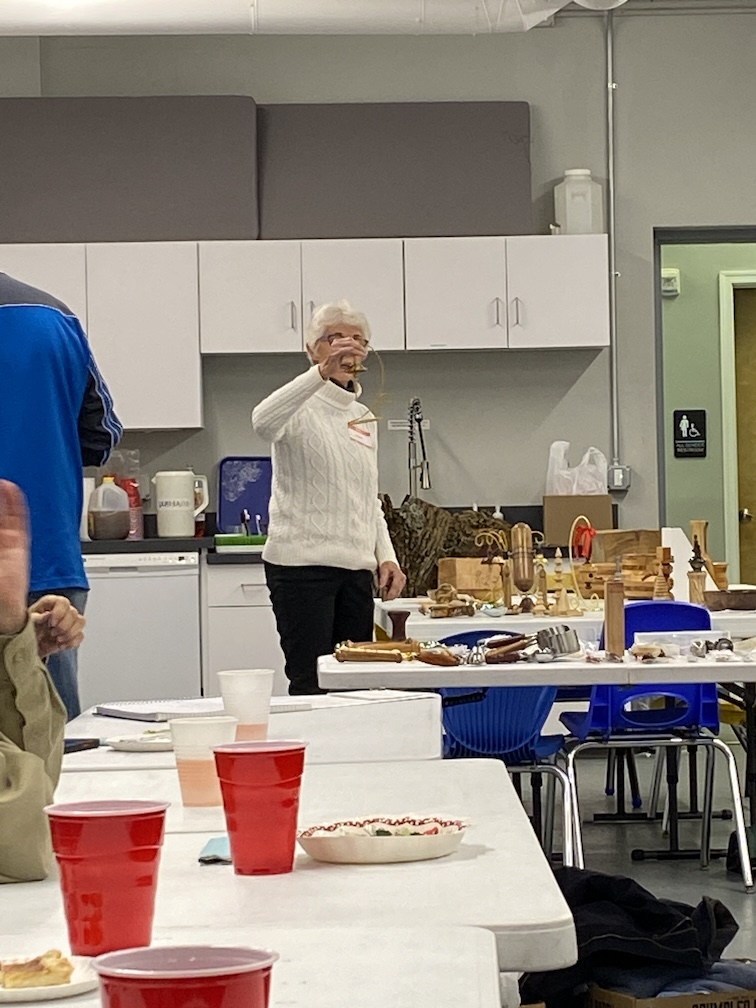

Paul Demmert discussed many different options of things you can make from skills gained after making pens. There are many things like coffee scoops, ice cream scoops, pizza cutters, measuring cups and spoons, and seam rippers which go together much like pens by tuning handles. You can find kits for such projects at places like Penn State Industries.

Some tips Paul shared from the classes he’s taught included:

- A mandrel saver works best for pen setup, protecting flexing of the mandrel

- Barrel trimmers works but can dull quickly, using a drill with a sander can be as effective

- CA glue fails due to weak shear strength, use 2 part epoxy to glue in brass tube, put plumbers putty or apple in the tube to keep glue from clogging the tube

- For threaded inserts use a bolt and washer to make them sit flat on the end of the blank when glueing

- Drill press works better than a chuck on lathe to drill blanks straight

- Washer over the hole of blank allows using a cone tailstock will help protect the blank from splitting