Our previously scheduled presenter had to cancel for personal reasons this month so our pivot was to watch a video about befriending the skew by Alan Lacer. If you have any reservations about using the skew, join us as we watch Alan break it down, show how to sharpen it, use it for 8 different cuts and discover why it can grab and how to avoid catches.

October 2021 Meeting

Dave Betler demonstrated his technique for making Stump Boxes. A turned box that he then carves and wood burns to create a realistic looking stump. We had a hybrid meeting using some equipment from the Rivet. Unfortunately the audio never really worked well enough for people watching at home which you’ll notice if you watch the video. Hopefully you can see how Dave does it despite the lack of audio.

June 2021 Meeting

We had an informative meeting this month all about segmented turning, thanks to a detailed slide show presentation with several samples on disply by Tony Omeis. We met at the Rivet with several others joining over Zoom. We expect more hybrid meetings like this in the future to allow for the most participation as possible. Thanks to all who joined us.

Our “try it challenge” for this month is to make your own segmented object. Give it a try and show us what you made at the next meeting in the fall. Enjoy the summer and make some shavings.

Show and tell examples:

April 2021 Meeting

We had another GREAT demo from a member’s shop, thanks to an outstanding presentation by Mike Lebo of how to make a thin necked goblet. Good attendance, great conversation and Q&A, made for a successful meeting during the pandemic. Thanks all who participated.

Our “try it challenge” for this month is to make your own thin necked goblet. Give it a try and show us what you made at the May meeting and you’ll get a chance to win something in our quarterly drawing.

February 2021 Meeting

This meeting was all about negative rake scrappers. The result was some information which may be helpful to everyone.

Everybody has their own favorite grid. Here are a few examples:

| Turner | Top Bevel | Bottom Bevel | Total Angle |

| Doc Green | 17.5 | 17.5 | 35 |

| Brendan Stemp | 22 | 22 | 44 |

| Cindy Drozda (Vortex Tool) | 25 | 25 | 50 |

| Brian Havens Sam Angelo | 30 | 30 | 60 |

| Glenn Lucas | 33 | 33 | 66 |

| Eric Lofstrom | 0 | 0 | 70 |

| Robo Hippy | 45 | 45 | 90 |

| Dave Schweitzer | 25 | 70 | 95 |

| Mike Waldt | 30 | 70 | 100 |

November 2020 Meeting

We had another GREAT Zoom meeting from The Rivet, thanks to an outstanding presentation by Mike Lebo of his latest wood threading tool. Good attendance, great conversation and Q&A, and some terrific “show and tell”s made for a successful meeting during the pandemic. Thanks all who participated.

Mike based his threading machine on Mike Peace’s design

October 2020 Meeting

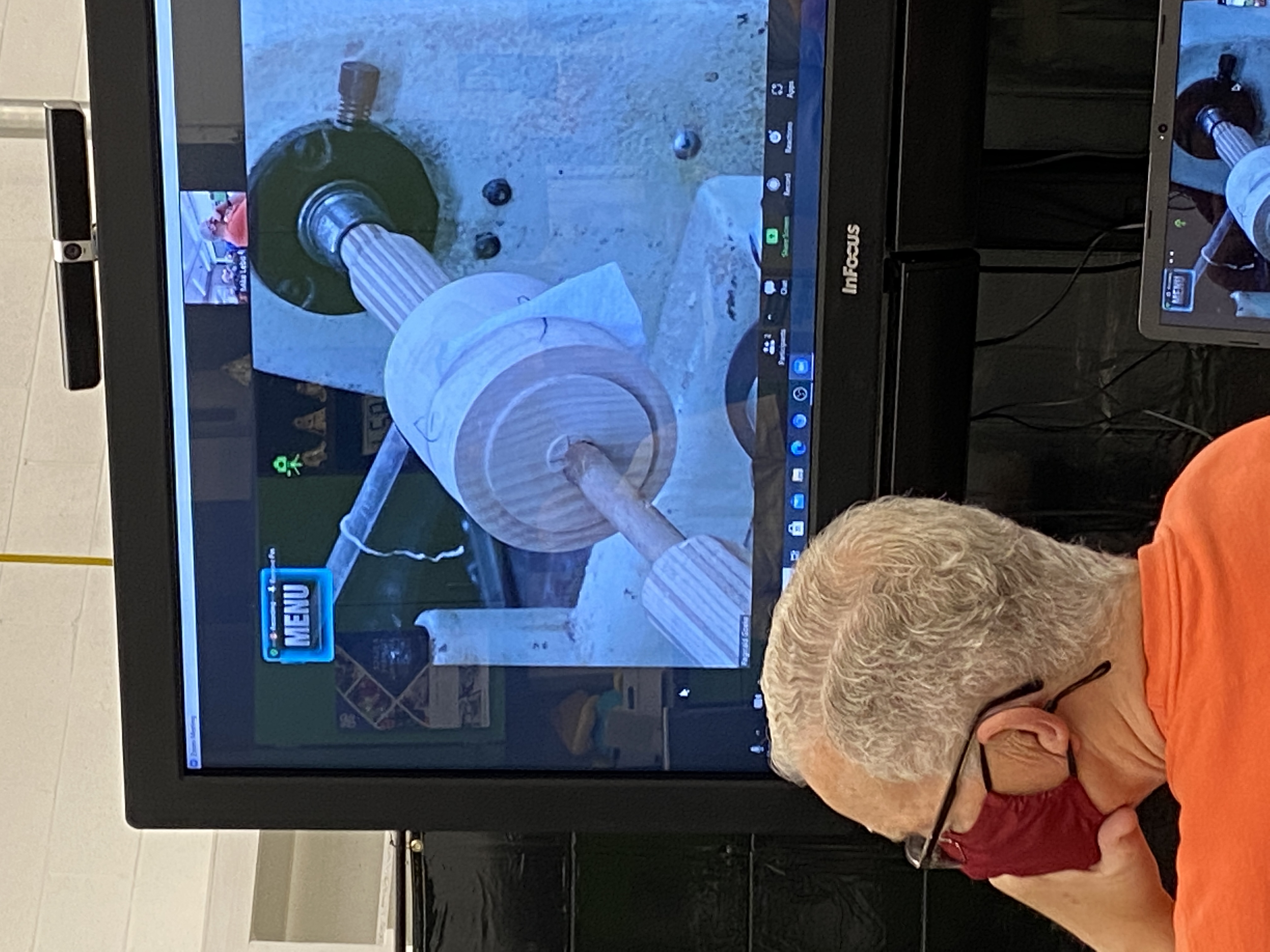

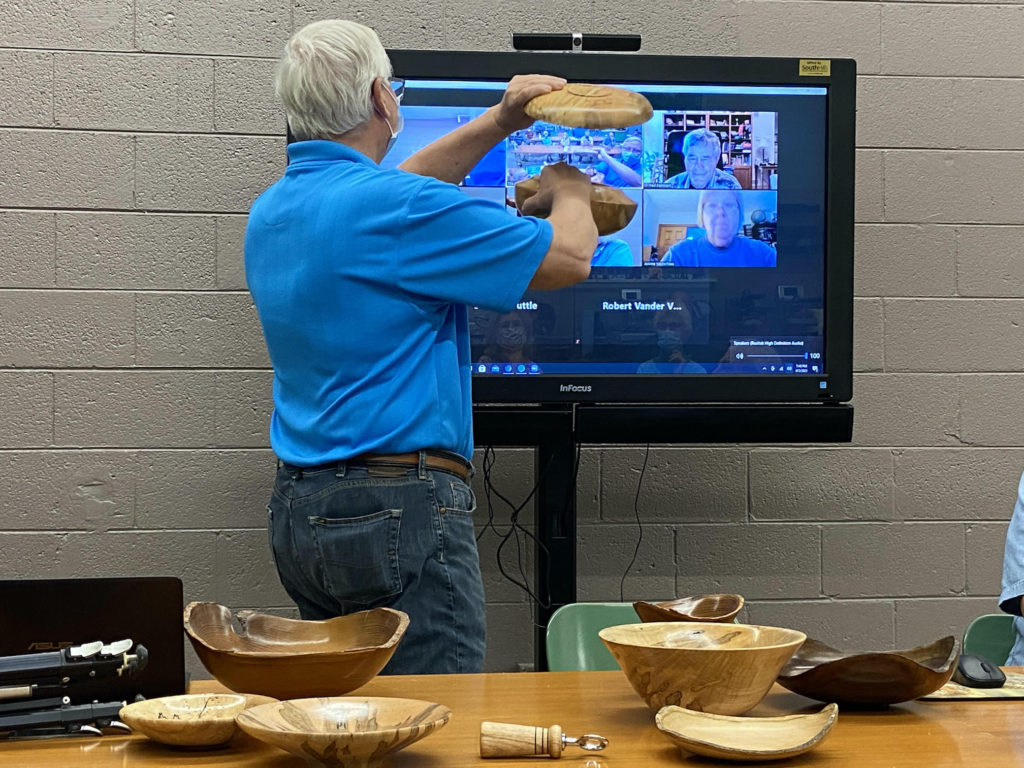

On October 1st we returned to the Rivet to use their facility and video streaming setup to host a zoom meeting with Jim Finley demoing making a baby rattle and hook tool usage and sharpening of a hook tool and double grind rake scraper. Some pictures of the event with a glimpse at how remote meetings are done.

There were 22 members in attendance (locally and virtually). We had 2 camera angles resulting in excellent video.

Several members who attended virtually reported that it was the best demonstration of tool use they had seen – and that the virtual format actually allowed them to see more than they could in a face-to-face meeting. We recorded the meeting and will distribute the link to all paid members within the next few days.

The winners of the gift certificates:

- Ken Vasko

- Mike Lebo

$20 each from Woodturnerswonders.com. We hope to make more opportunities for members who join our Zoom meetings

MANY THANKS to folks at The Rivet who provided much needed equipment and hours of their time to make our meeting successful. Our collaborative relationship with The Rivet is benefiting both of us. They are providing opportunities for us to sell our own works for our own profit. They are providing opportunities for us to help them sustain the Makers World. They are making opportunities for us to teach classes and to have a lathe available for members who don’t have their own. This has become a very productive relationship, and we hope you will continue to do everything possible to support it.

March 2020 Meeting

Our March meeting occurred on the 5th, just before all the masks and lockdowns came into full force due to the COVID 19 pandemic. We setup 4 lathe stations at the Rivet and had 4 turners demonstrating different techniques. Attendees could go around and watch, ask questions and even try their hand at the lathe. The topics were:

- Hollowing/End Grain – hook tool, spindle gouge, square scraper

- Skew chisel

- Chucking – tenon, jam chuck; shear cut on outside of bowls

- Roughing, beads and coves

Videos taken during the event can be found here:

February 2020 Meeting

Jim Finley shared his perspective on getting the most out of each piece of wood by considering grain and mounting the piece in the most beneficial position.

As Jim’s says: “Wood is essential to our hobby – woodturning. Finding turning wood, free or otherwise, is challenging, fun, and may provide opportunities to make new friends and provide access to myriad species and unique cuts. Sometimes, the most interesting finds are things you might overlook.” At this NVWT meeting, he talked about, which cuts to take for figure or interesting grain, unique species (common and uncommon), and diseases that create spectacular wood and how to take advantage of the figure you find in wood.

People brought along their own unique examples of wood to get advice.

He also explored different approaches for mounting special finds on the lathe. Surprising to many of us, he usually avoids faceplates and turns between centers. A 2 prong spur can grip better because it will go deep when aligned with the grain.

We also had our normal Instant Gallery (aka show and tell)

January 2020 Meeting

Our January 2020 meeting presentation was on sharpening using a variety of tools, jigs and techniques brought to us by Jim Finley, Dan Kozar, and Reg Goeke.

Checkout our YouTube channel for some video highlights

Some member made items for show and tell:

A typical wood auction:

Some notes on sharpening from Dan:

Start by choosing the angle of the grind. The angle that a tool comes with may not be correct. A good starting point is: 35° for spindle gouges, 60° for bowl gouges, 25° for skews and parting tools, and 80° for scrapers. 2 0r 3 degrees either side of these numbers is fine. New tools almost always need sharpened before you use them, even if the angle is correct.

I use the Wolverine, also called the Oneway system for all my sharpening.

I sharpen roughing gouges, skews and scrapers on the Wolverine platform. The combination of the angle of the platform, and the distance of the platform from the wheel, determine the angle of the grind on the tool.

I sharpen spindle and bowl gouges with the Wolverine Vari-Grind jig. This jig is tricky to set up. For spindle gouges I set the arm of the Vari-Grind near the top of the jig, and for bowl gouges somewhere around the middle. The first thing is to get the correct angle. If the angle of the tool is correct, put the arm of the Vari-Grind in the pocket of the long arm of the Wolverine system, and slide it in and out until the bevel of the tool matches the wheel exactly. To check this, I shine a flashlight on one side of the tool where it meets the wheel and look at the other side of the tool to see in any light shines through. If light shines through at the top (edge) of the tool, pull the long arm out a wee bit and try the light again. If light shines through the bottom (heel), push the long arm in. Once you have it adjusted that no light shines through, you are good to go. You can also check the angle by using a black magic marker to paint the bevel of the tool black. Put the tool in the jig in the long arm, rest the tool on the wheel, and rotate the wheel by hand 3 or 4 revolutions. If you have a shiny strip from top to bottom, you are good to go. If you see black at either the top or bottom, adjust the long arm as if you see light shining there. But every time you adjust the long arm, you have to repaint the tool bevel.

If you want a different angle than what is already on the tool, or you change the position of the arm on the Vari-Grind, start by matching the bevel to the wheel by eye. It doesn’t have to be exact. Push the long arm in if you want to go to a sharper angle. Say from 40° to 35°. Or pull the long arm out, if you want to go to a less sharp angle. Say 35° to40°. After each adjustment, check the angle of the bevel.

If you are using stone wheels on your grinder, you will need to adjust the position of the long arm every 2 or 3 times you dress the wheel. Every time you dress the wheel, it gets smaller. As the wheel gets smaller, and you don’t reposition the long arm, the angle of the bevel gets less sharp.

If you have CBN wheel, you never have to dress it. Therefore, you canmeasure the distance between the front of the pocket of the long arm, and the base it slides in, and cut a piece of wood to this length. Label the block of wood as to which tool it is for. Do this for each type of tool. Then you can easily use the block of wood to adjust the position of the long arm for each tool type. No need to use the flashlight, or magic marker when you go from a spindle gouge to a bowl gouge.

When grinding, exert VERY LITTLE pressure against the wheel. Hold the tool near the jig, NOT at the end of the handle. Watch the shape of the tool as you grind, and keep the tool moving. If you hold the tool in one position, you will get a flat spot.

Sources:

Sharpening Woodturning Tools Book available from AAW

Sharpening turning tools 71-page article on AAW website

Don’t expect to a get a perfect grind on your first try. It takes practice !