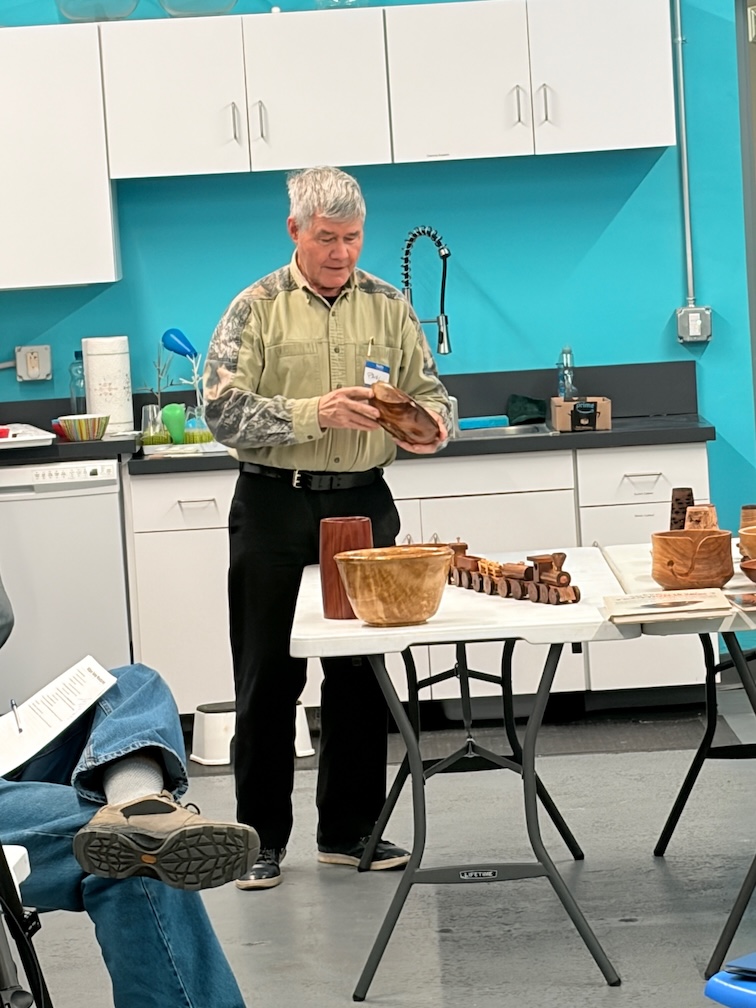

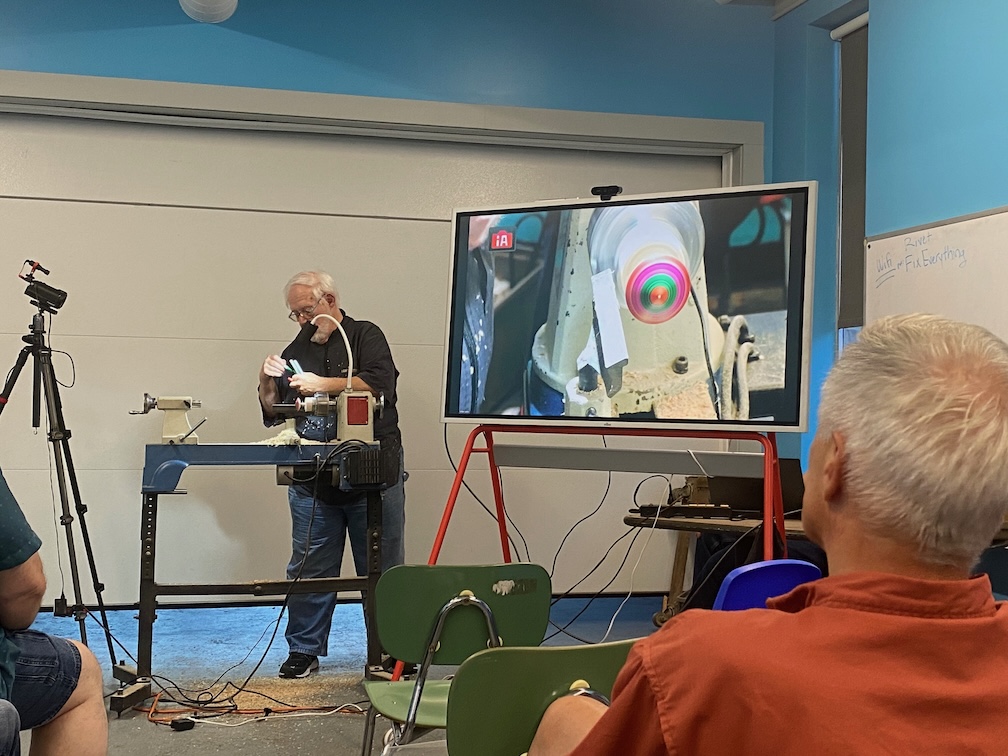

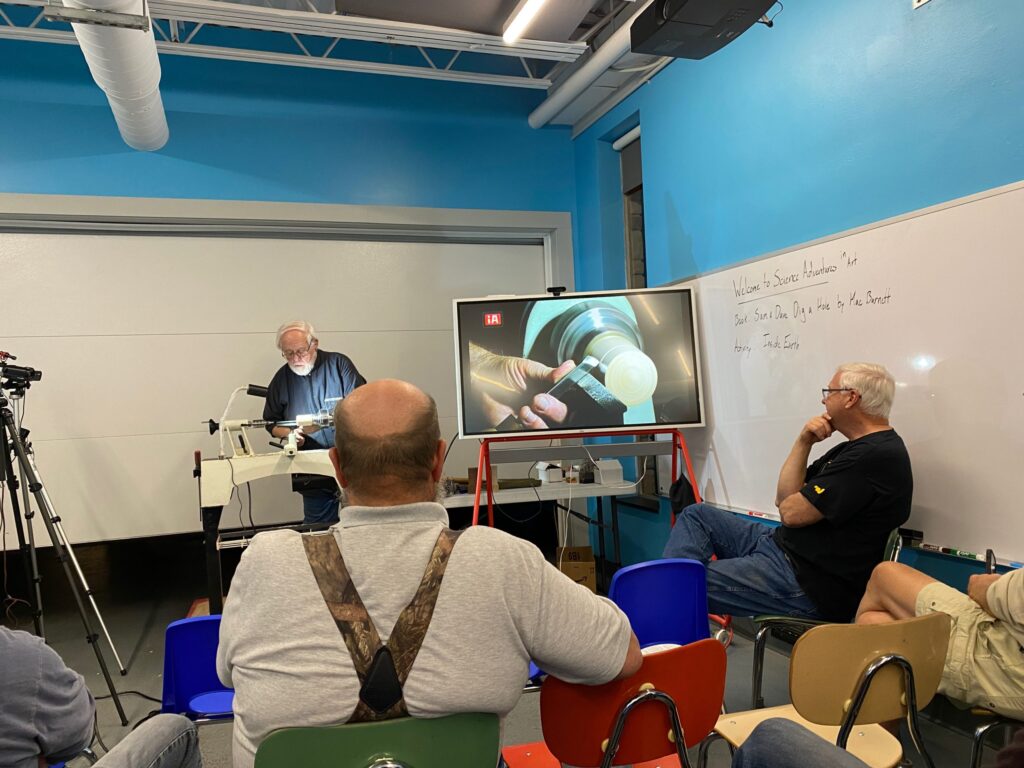

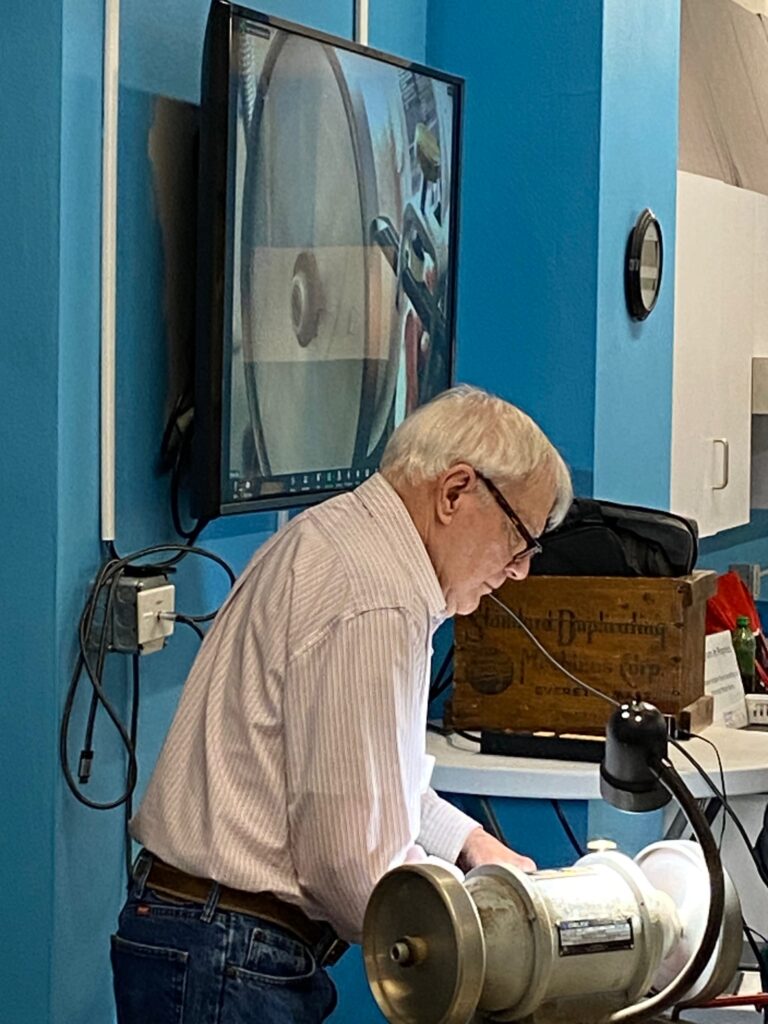

Our November meeting included normal business and updates, show & tell, a presentation by Wes Glebe on his creative process and the sale of 2 of the club’s older lathes to two lucky members.

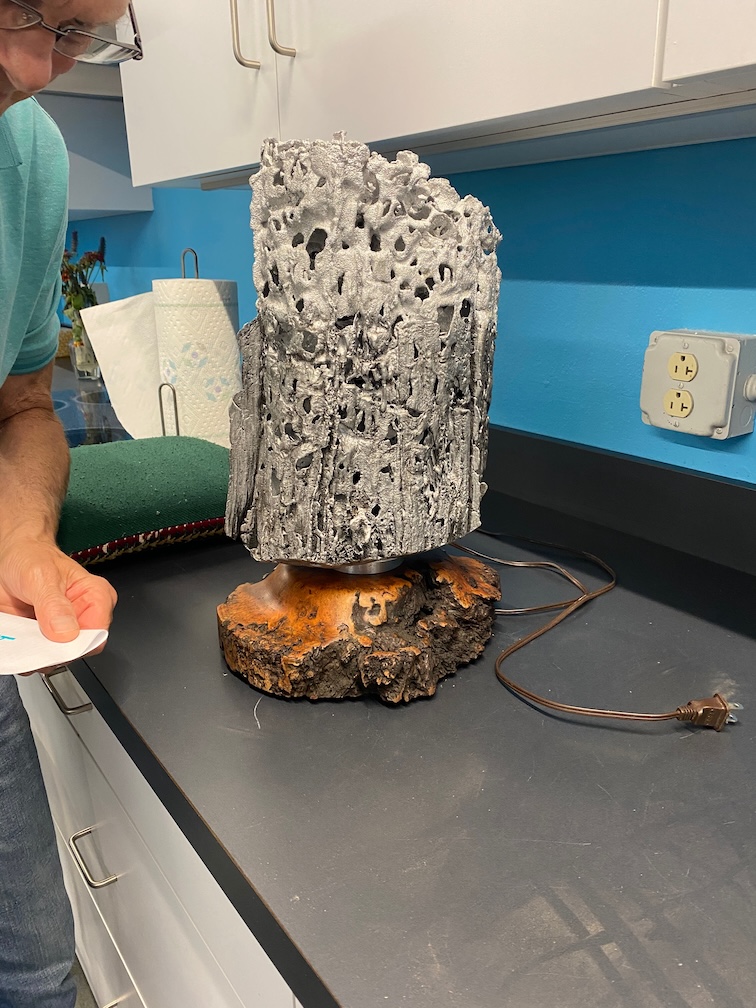

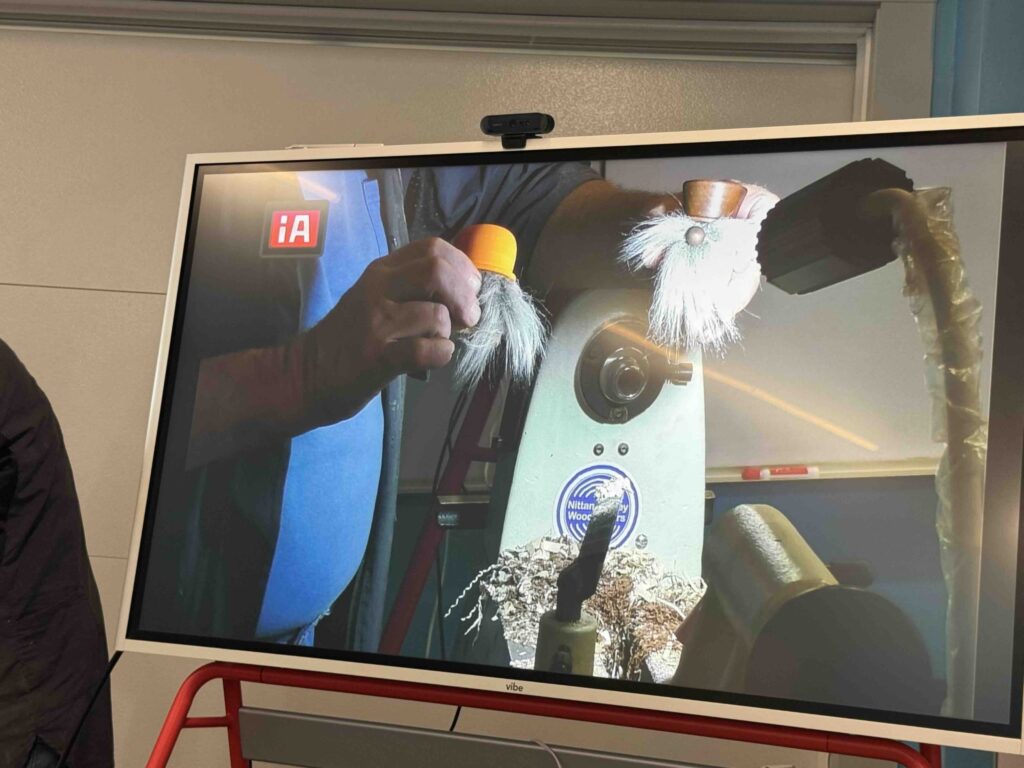

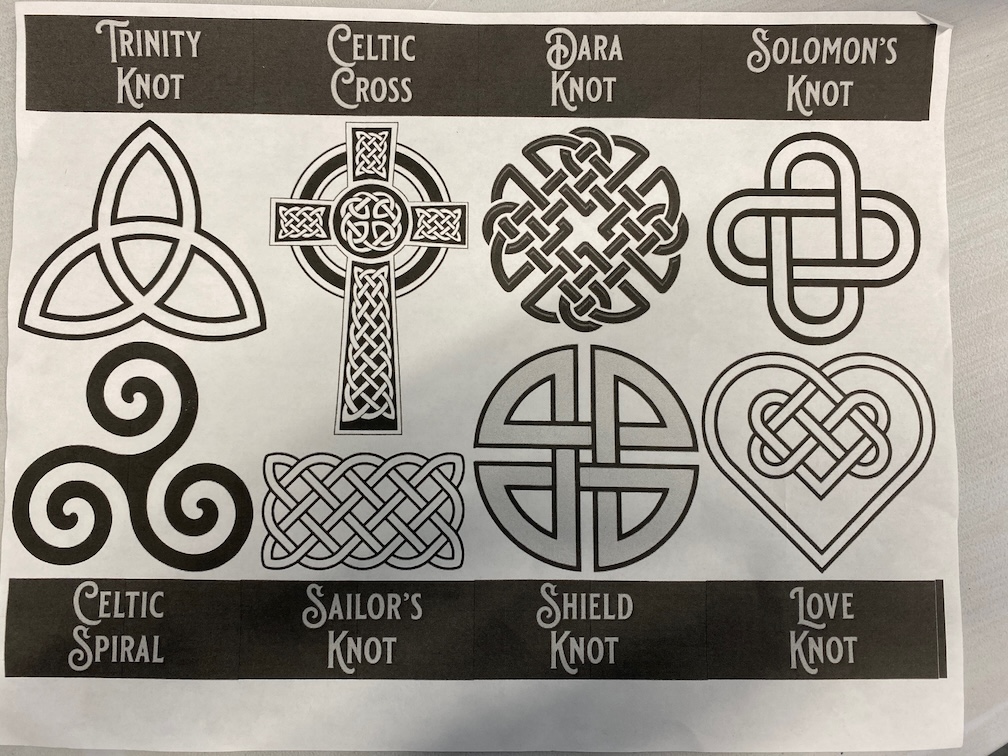

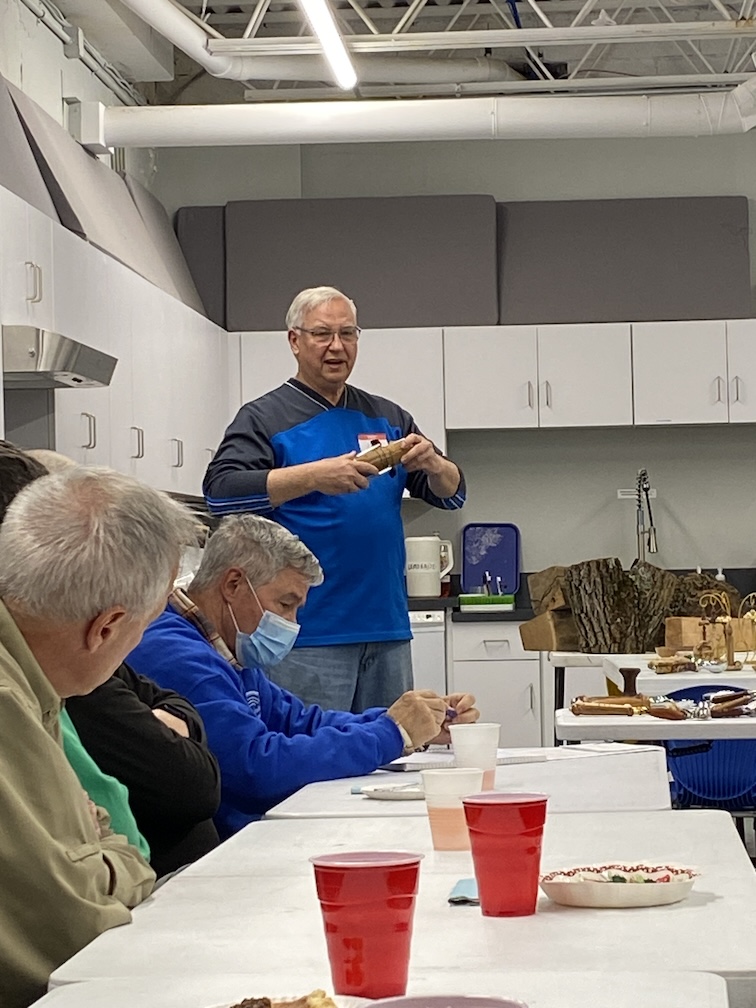

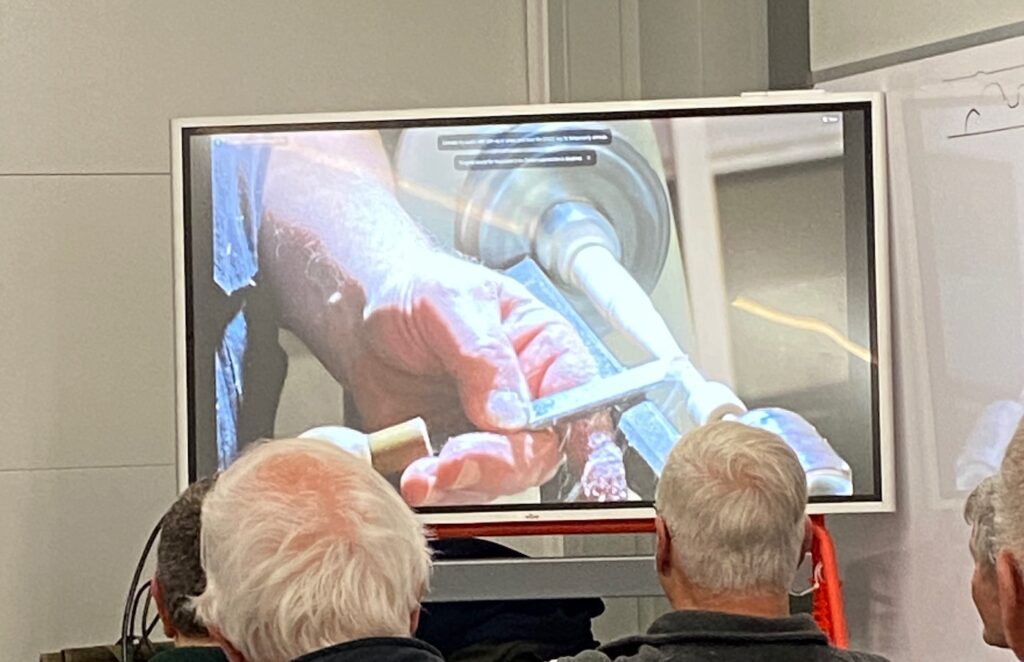

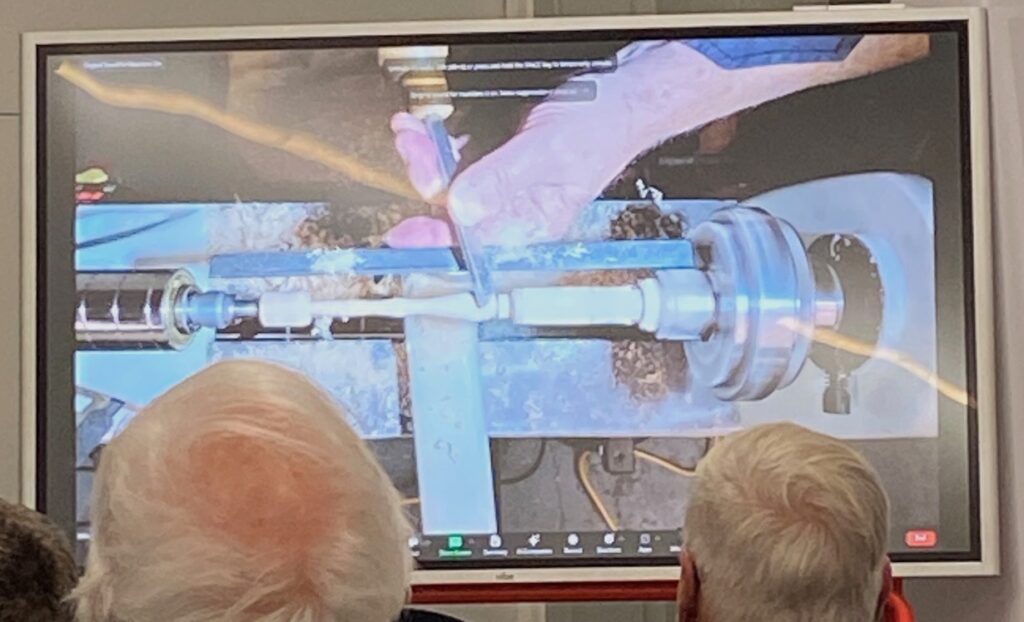

Wes is an artist using all sorts of materials and he used brass sheet metal ornaments as an example of how is creative design process works. A key take away was to experiment with many different tools and play until you find something that clicks and a design which works for you. He starts without an idea or plan or design and loves the exploratory process as much as the finished product. It’s a strategy which works will in turning as well when you throw a chunk of wood on the lathe it’s easy to play with different tools and techniques until you create something which clicks for you. Free yourself to explore.

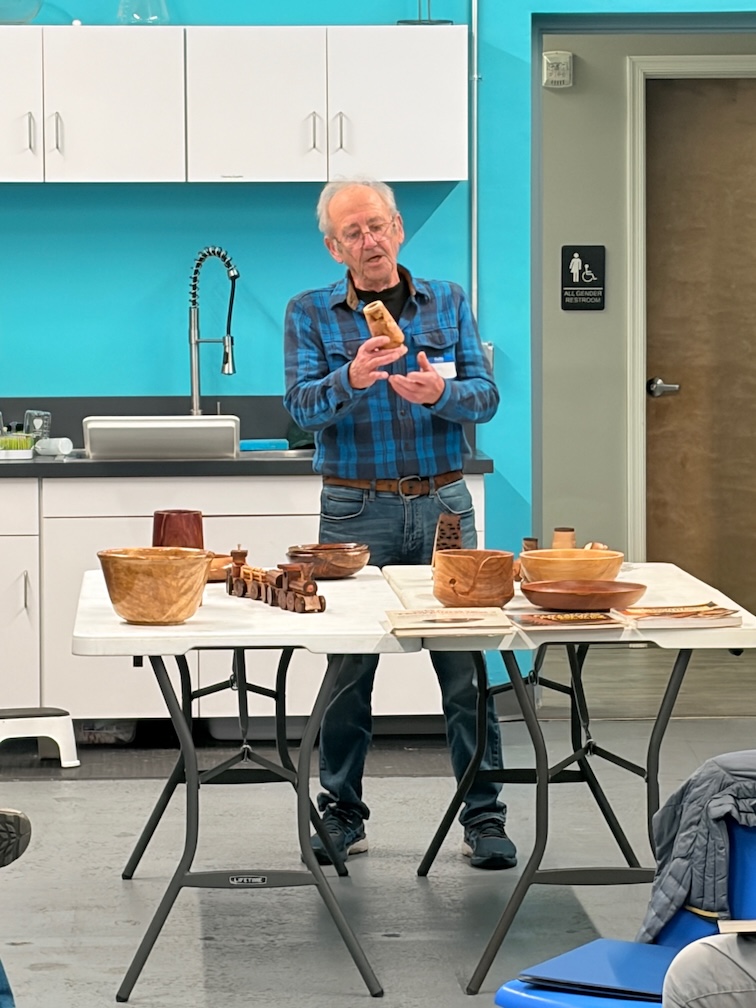

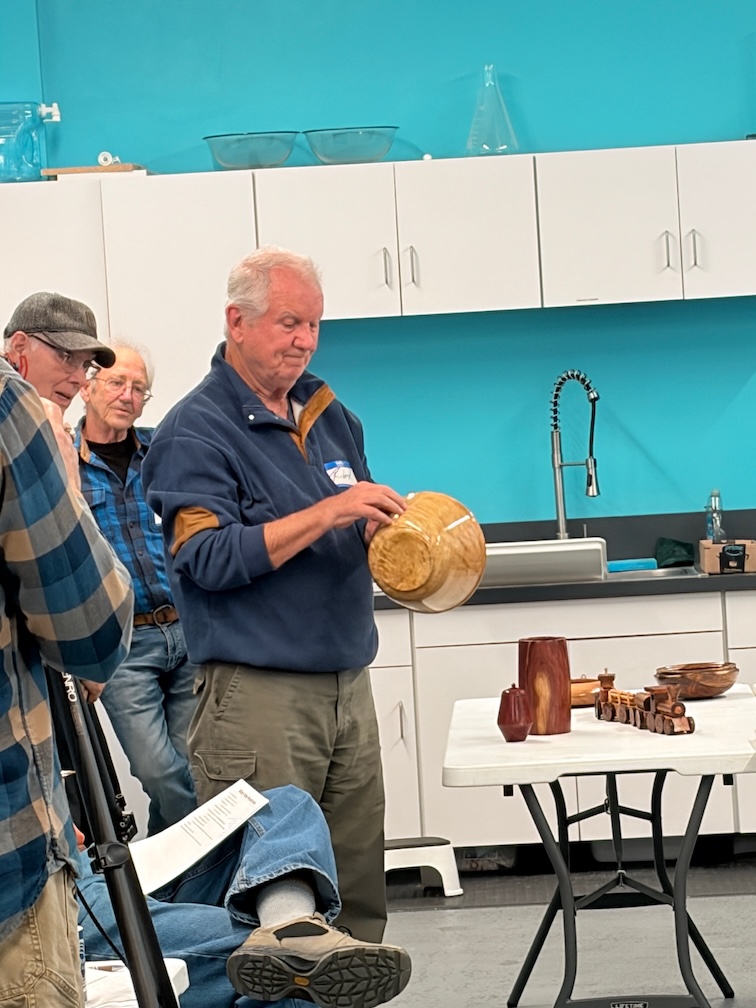

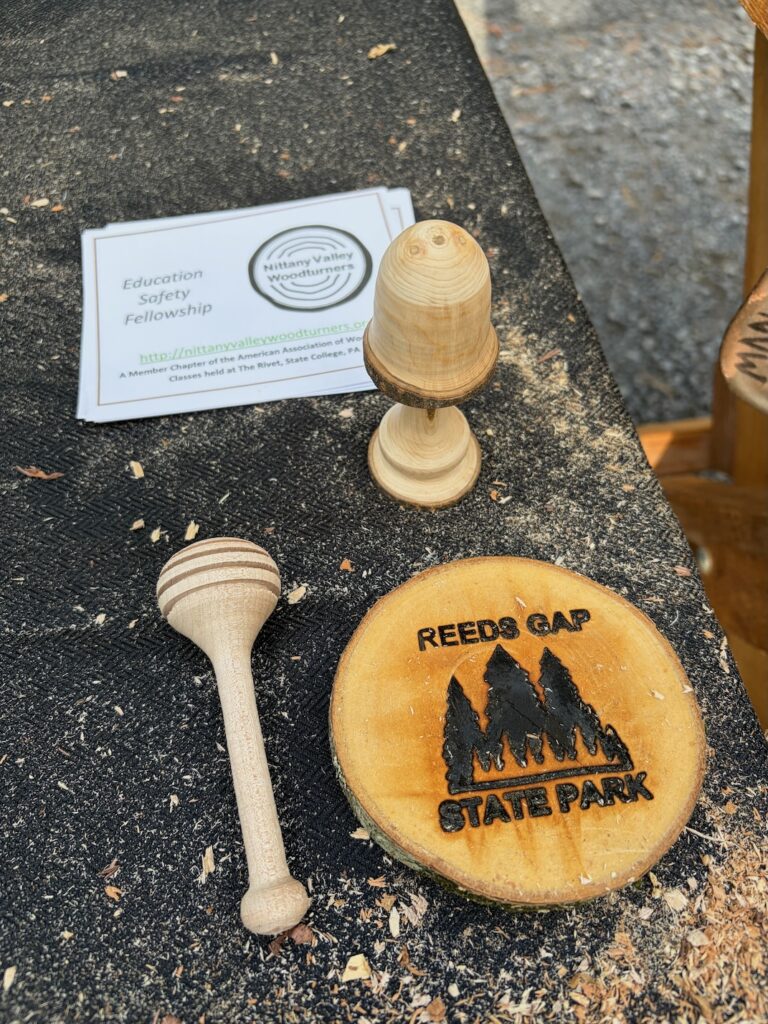

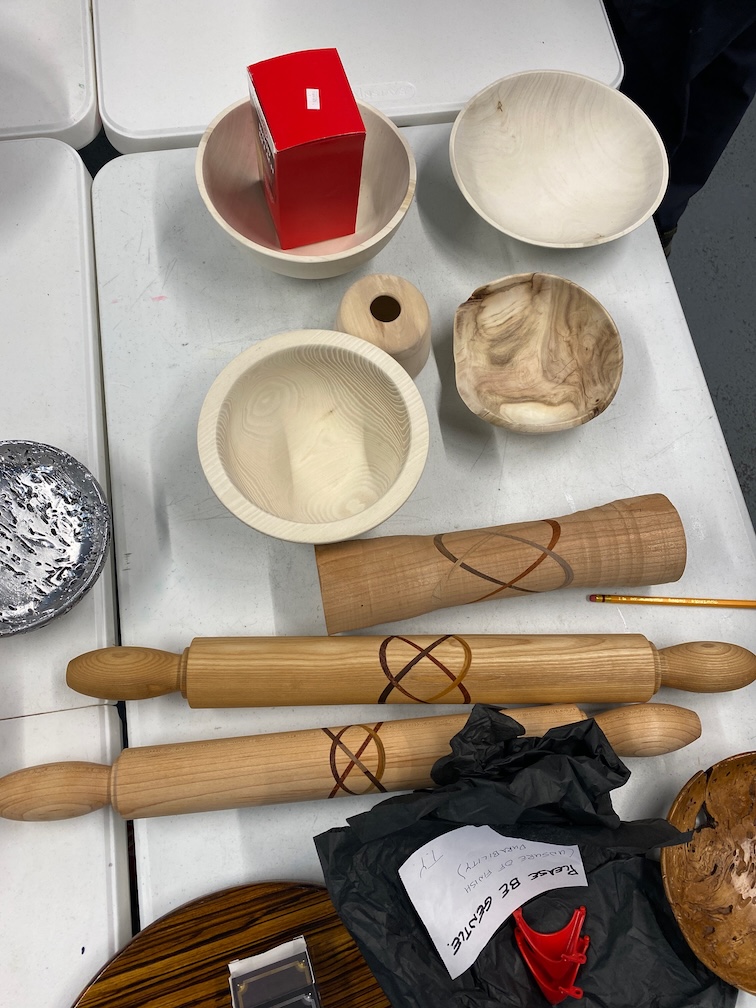

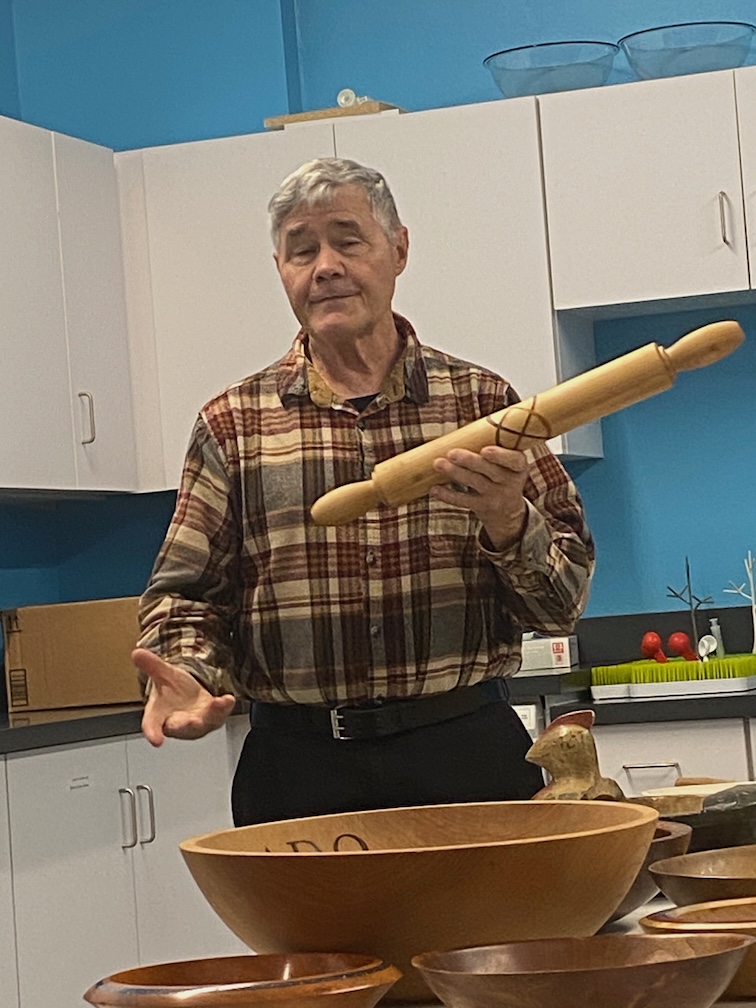

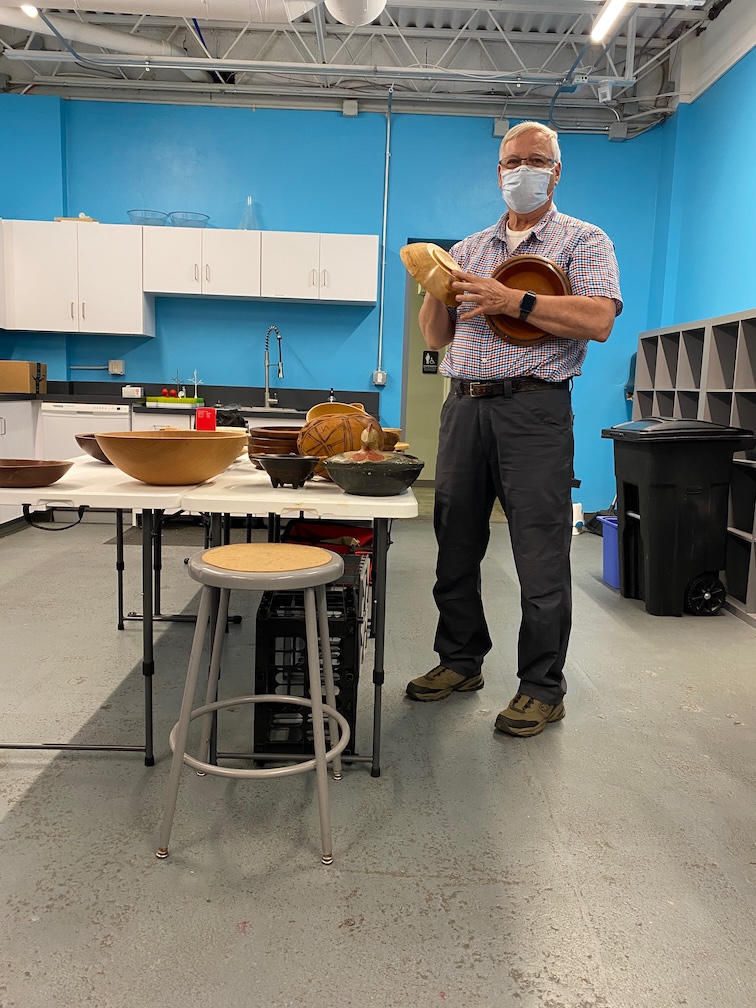

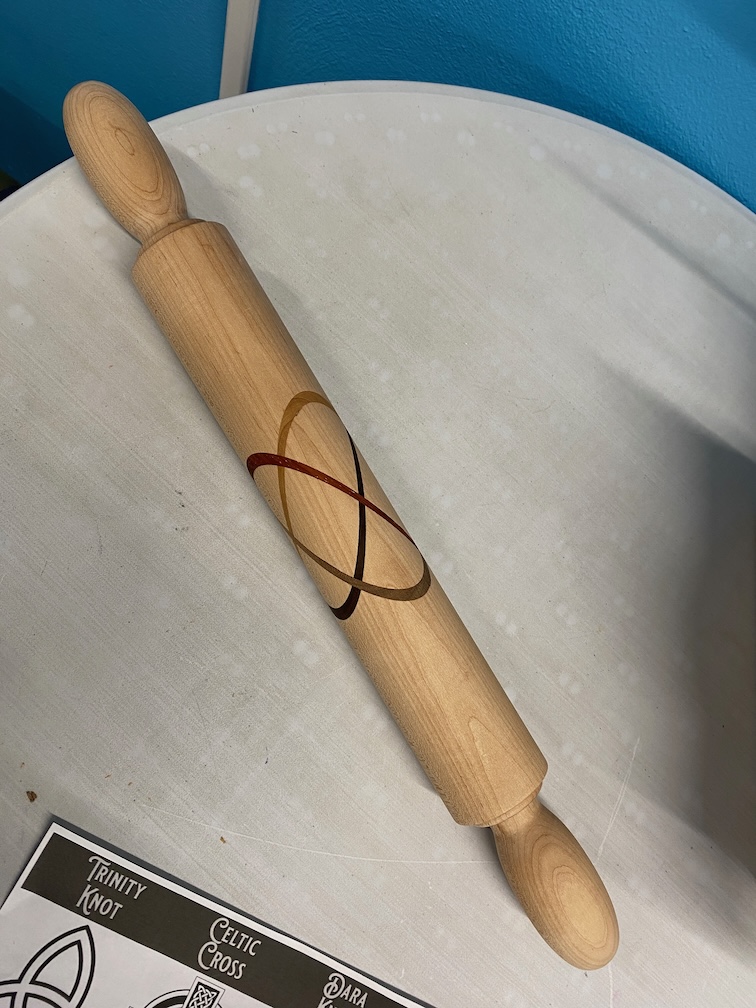

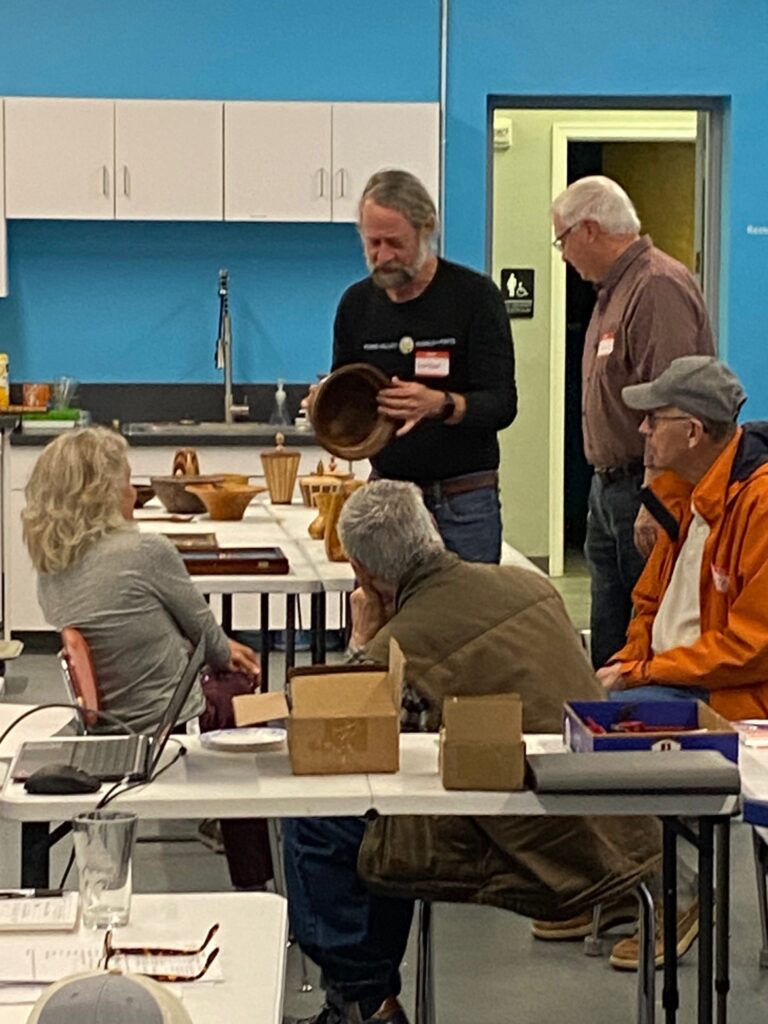

Show & Tell included many great examples of the talent within our club.