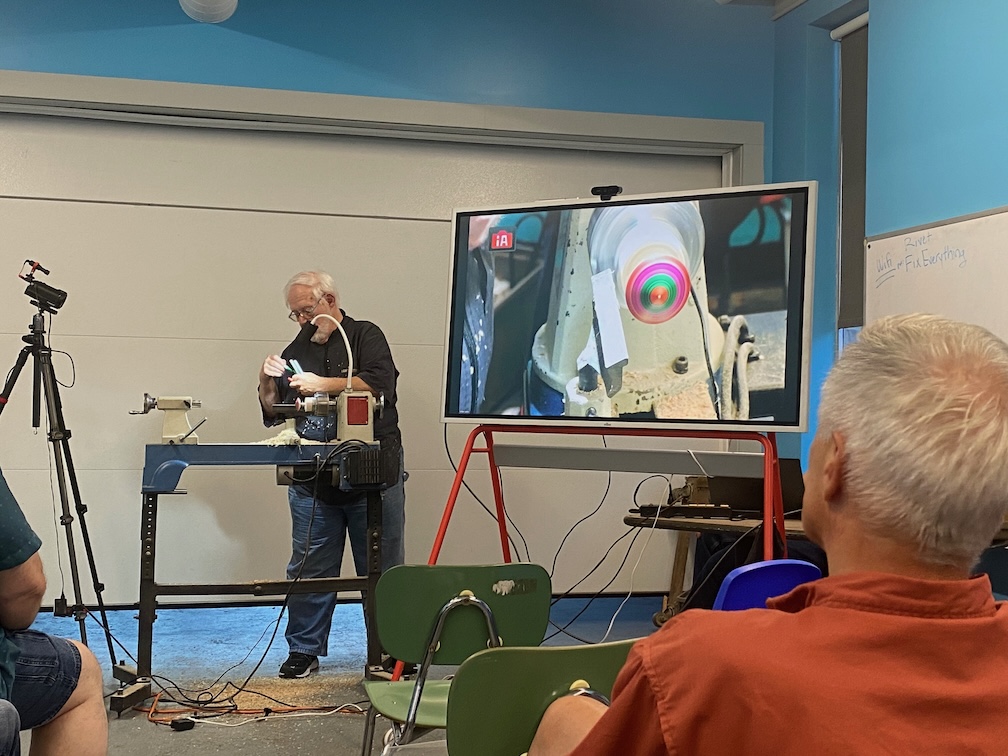

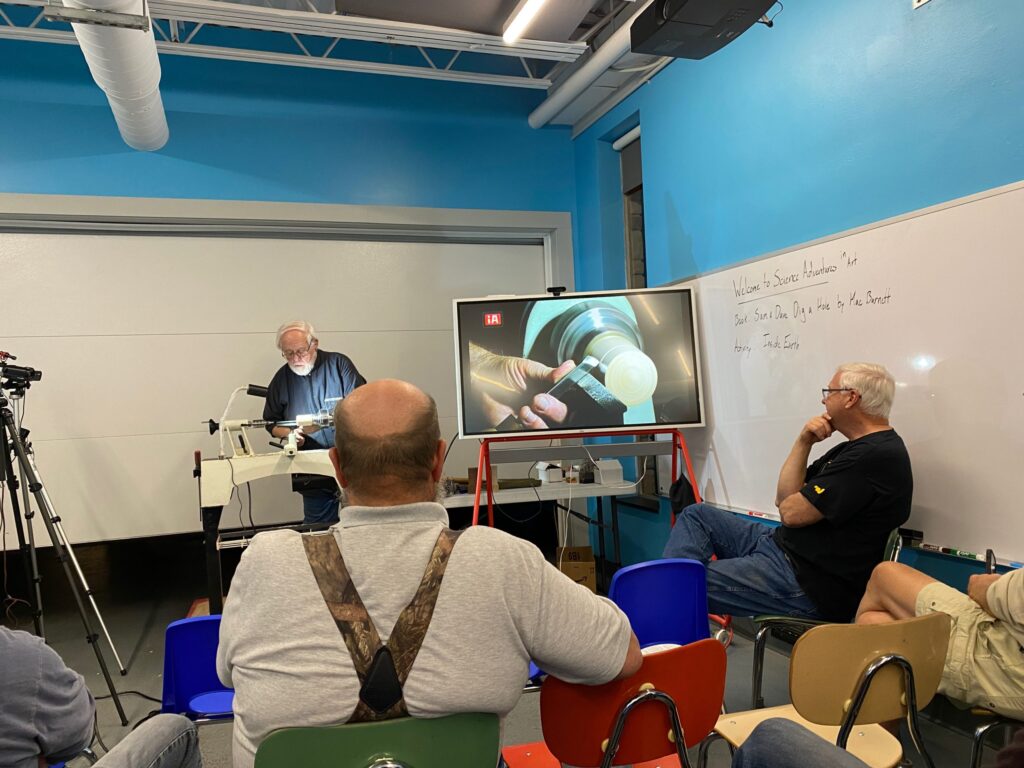

We had a presentation covering lathe maintenance from the wisdom and experiences of Paul & Ken.

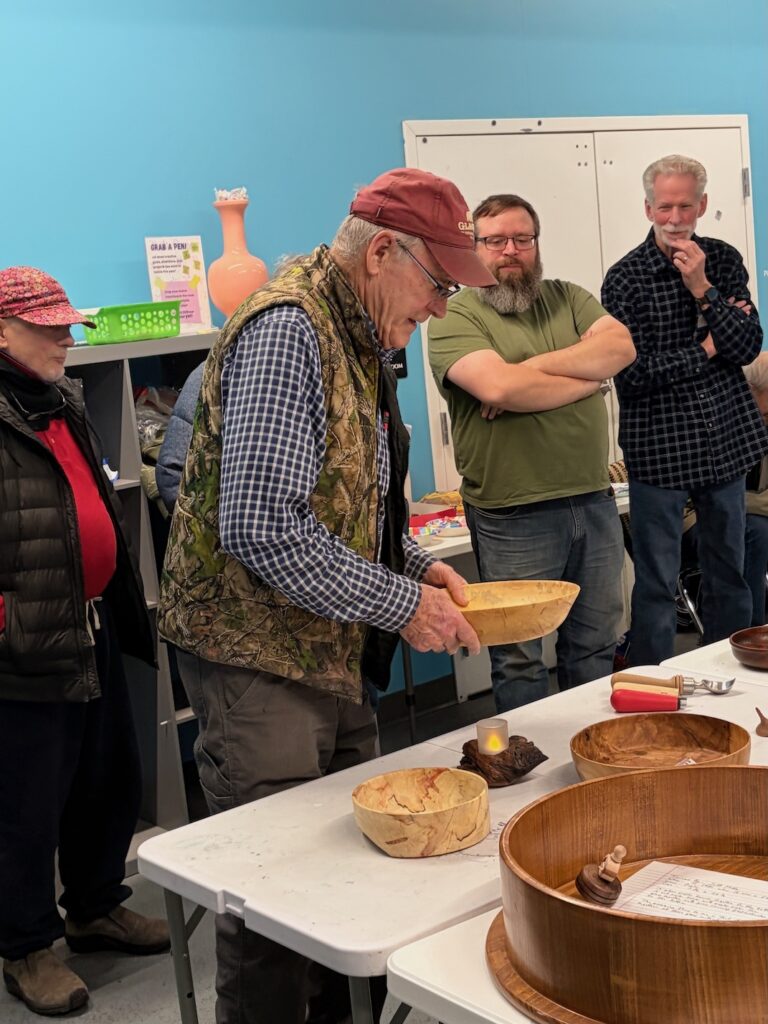

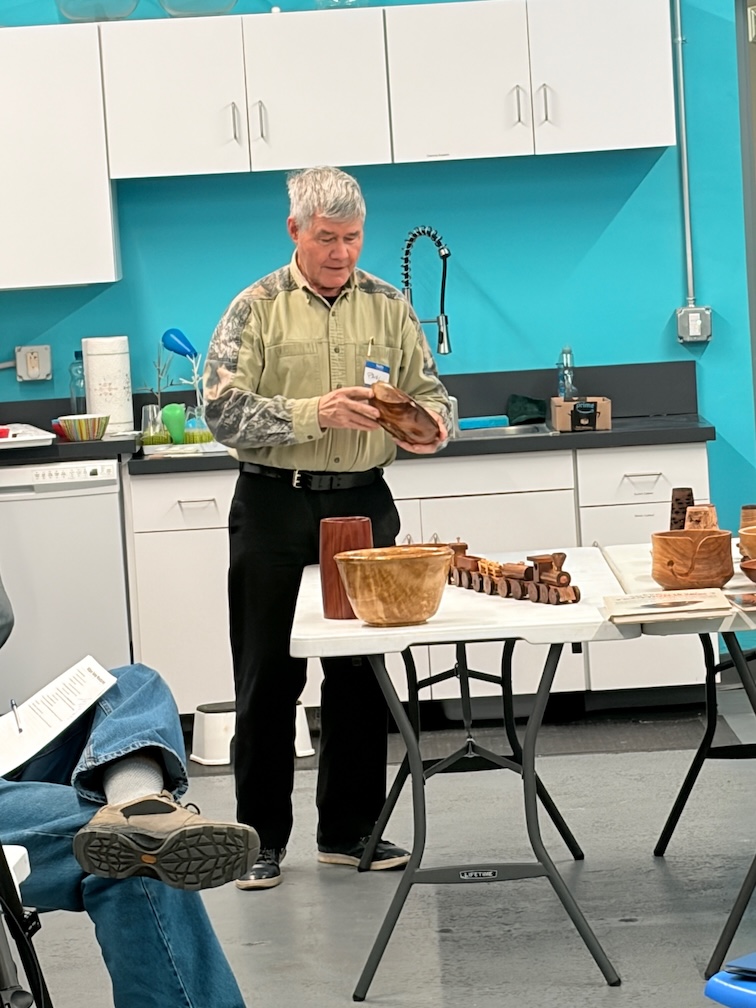

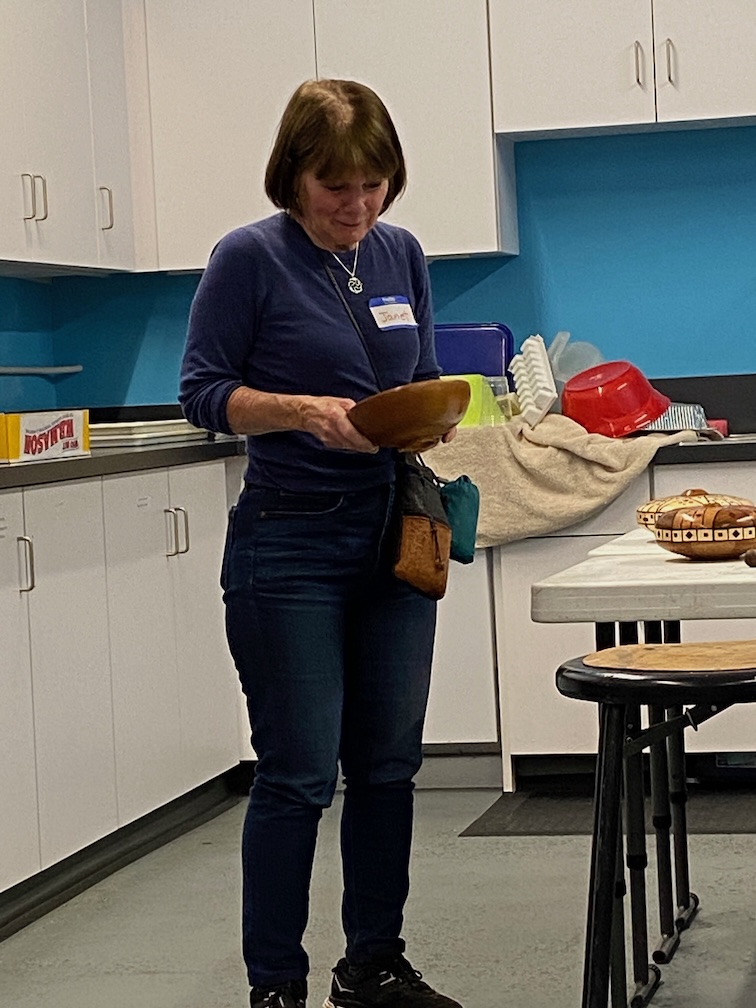

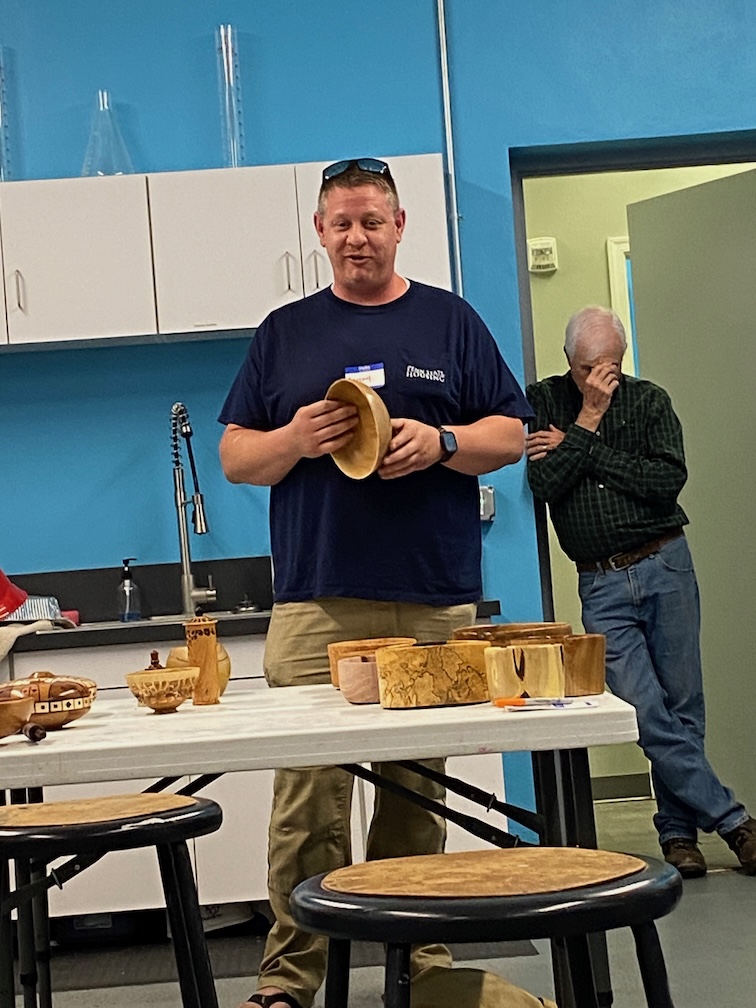

Show & Tell

We had a presentation covering lathe maintenance from the wisdom and experiences of Paul & Ken.

Show & Tell

We had our Christmas party pot-luck get together with great food, show and tell, a wood auction, and lots of hanging out with each other. The president’s challenge was to make an ornament, so the show & tell included a ton of great examples.

The pot luck was a great spread of delicious food.

Check out all the great examples of member ornaments and other turned items.

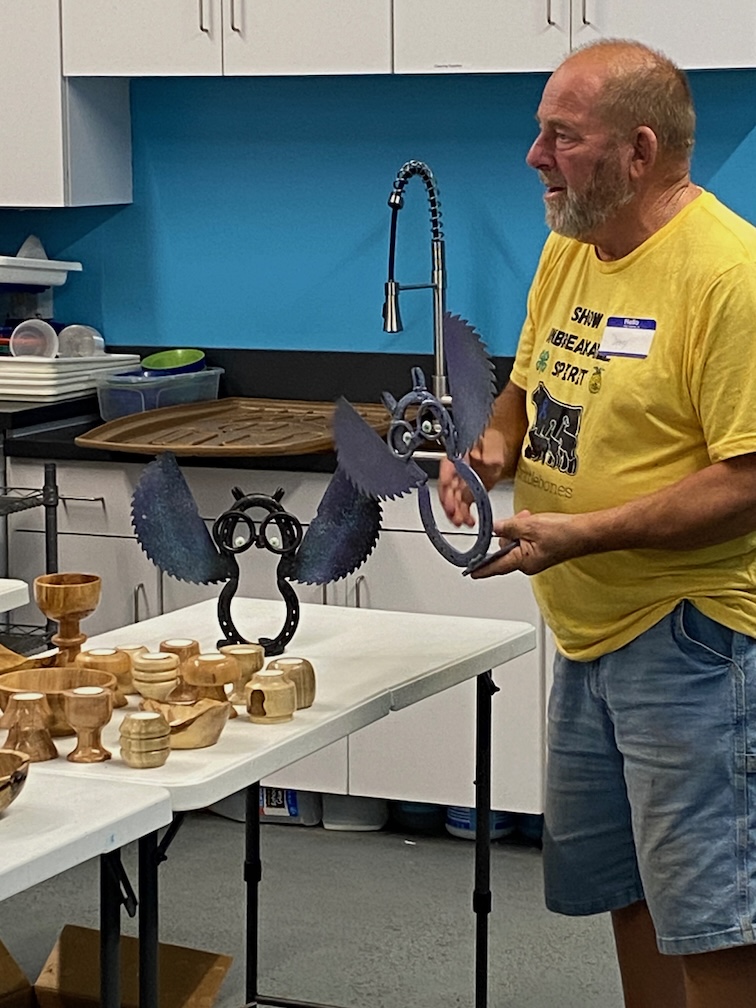

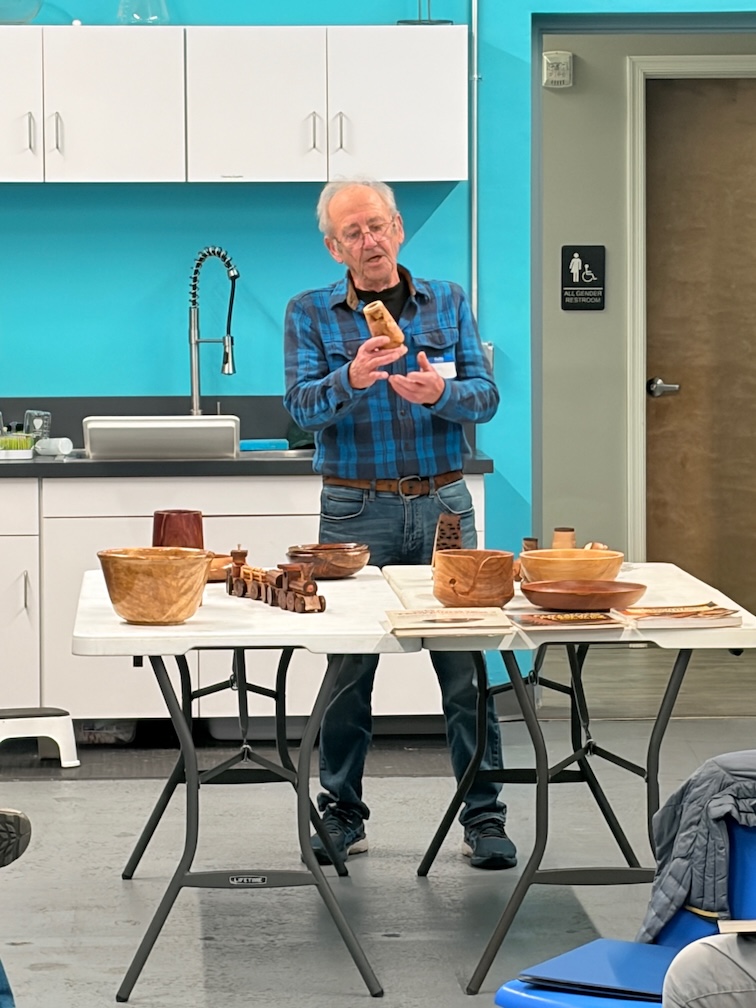

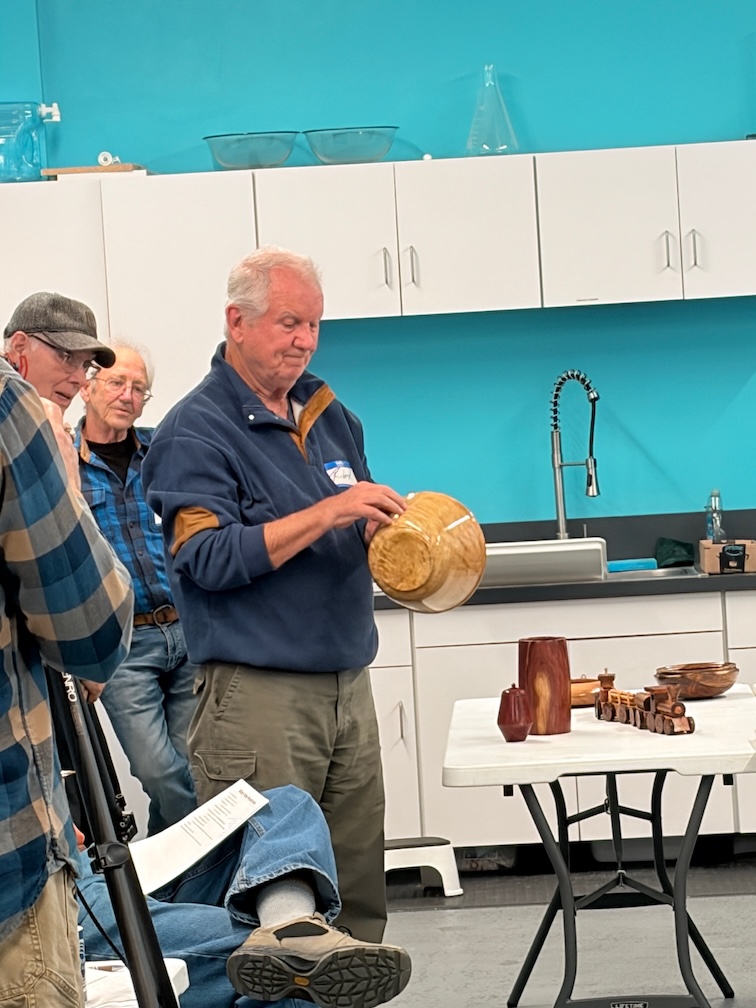

Our November meeting included normal business and updates, show & tell, a presentation by Wes Glebe on his creative process and the sale of 2 of the club’s older lathes to two lucky members.

Wes is an artist using all sorts of materials and he used brass sheet metal ornaments as an example of how is creative design process works. A key take away was to experiment with many different tools and play until you find something that clicks and a design which works for you. He starts without an idea or plan or design and loves the exploratory process as much as the finished product. It’s a strategy which works will in turning as well when you throw a chunk of wood on the lathe it’s easy to play with different tools and techniques until you create something which clicks for you. Free yourself to explore.

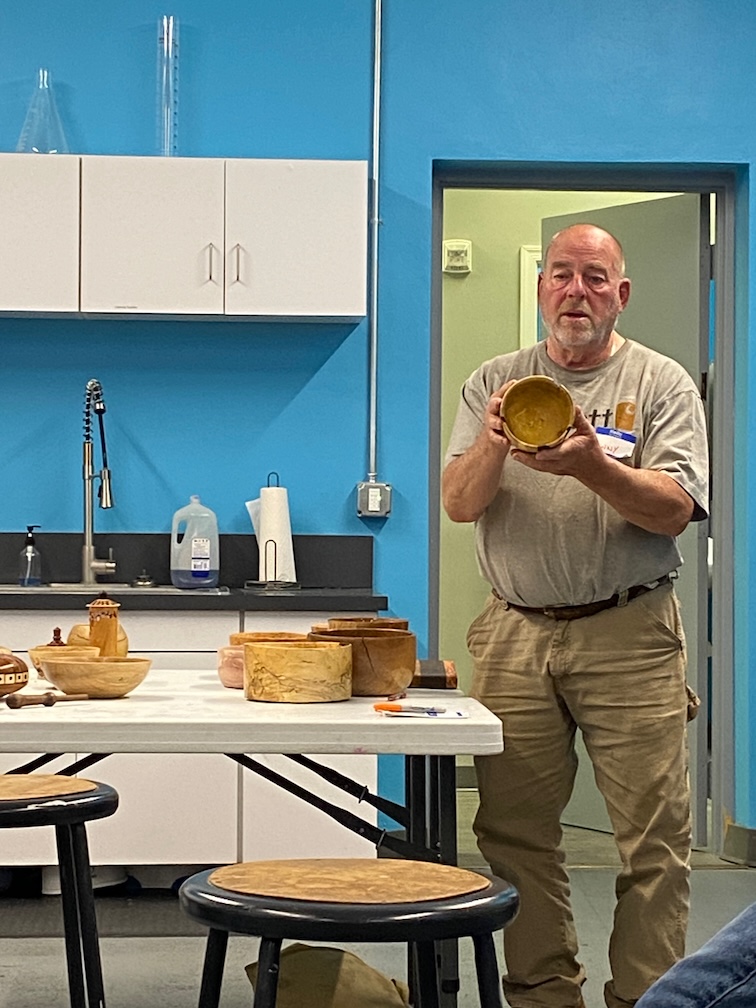

Show & Tell included many great examples of the talent within our club.

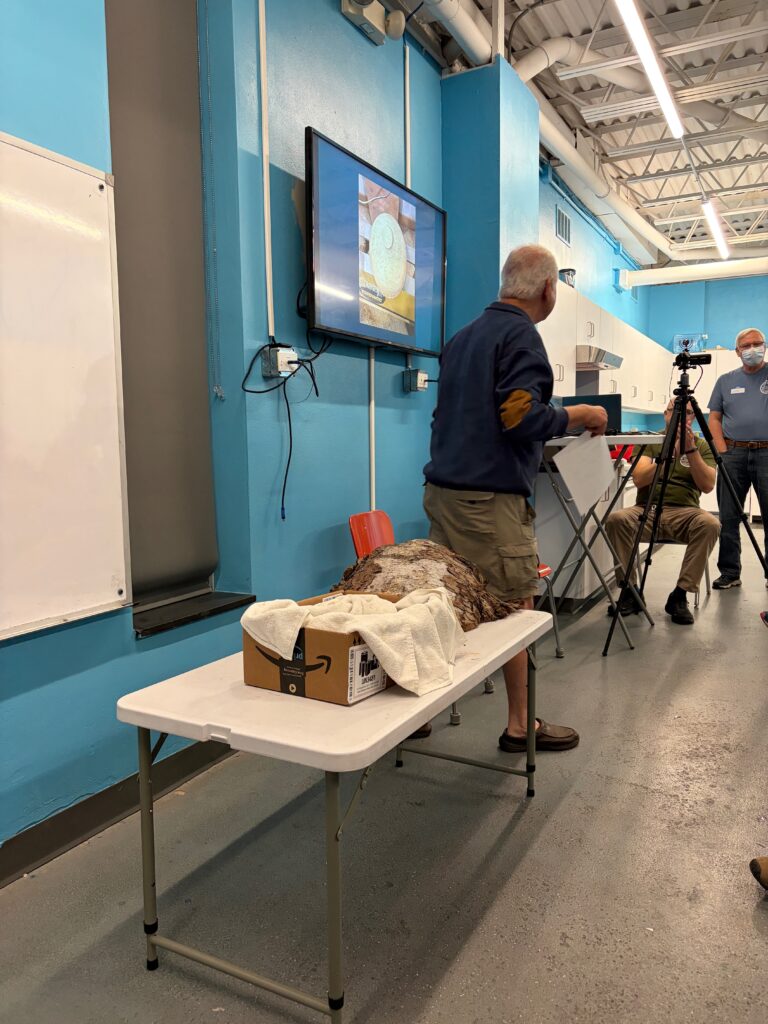

Our October meeting included a presentation about turning a bowl out of a white cedar burl and debrief of the recent woodturning symposium from Jeremy Sinclair and our normal show & tell and wood auction.

Richard Garland’s Presentation

Richard Garland provided a slide show demonstration titled “Tree to Bowl –

White Cedar Burl”. Below you can see the log with the Burl which was cut from the log and cut in 2 pieces, one of which, Richard prepped for the lathe and turned into a large bowl with great grain. One challenge was dealing with tear-out due to the grain and softness of the cedar. Nice bowl.

Jeremy’s Tour of the Symposium

Everyone enjoyed Jeremy Sinclair’s enthusiastic summary and slide show of the

Lancaster Mid-Atlantic Woodturning Symposium. Amazing world renowned woodturners were there to demonstrate their skills and teach attendees the tricks of the trade. Vendors were also there to show off their products with many opportunities to find deals and pickup the tools you need. We hope that more members will attend next year’s event the 3rd week, September 2026.

Show & Tell

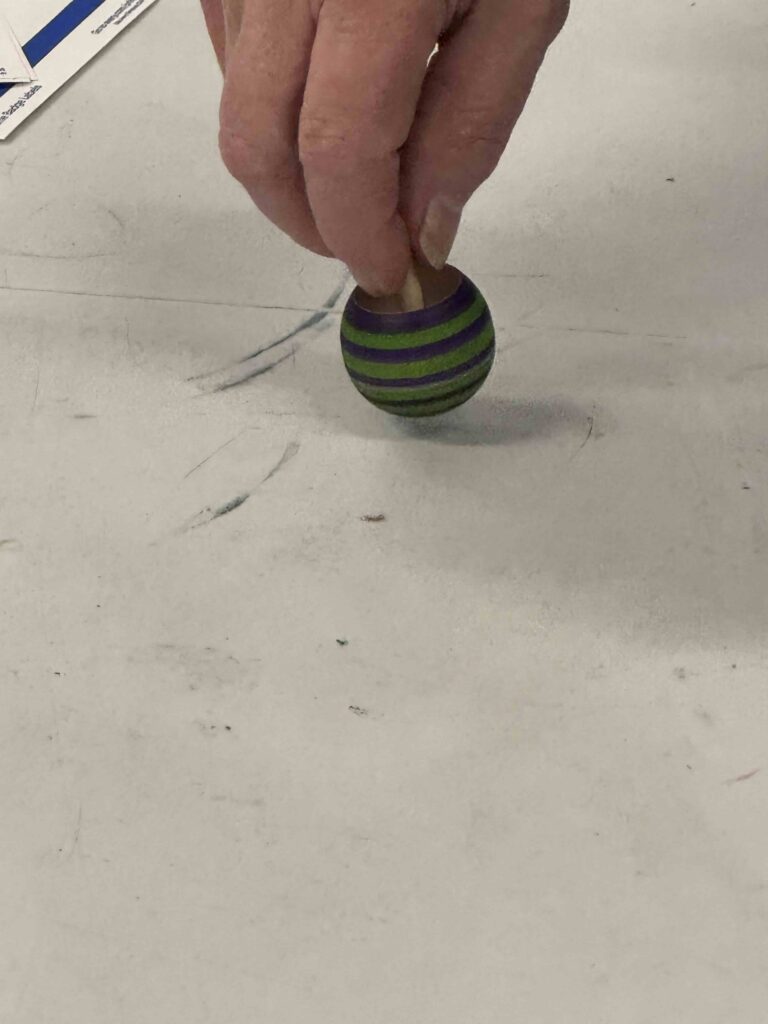

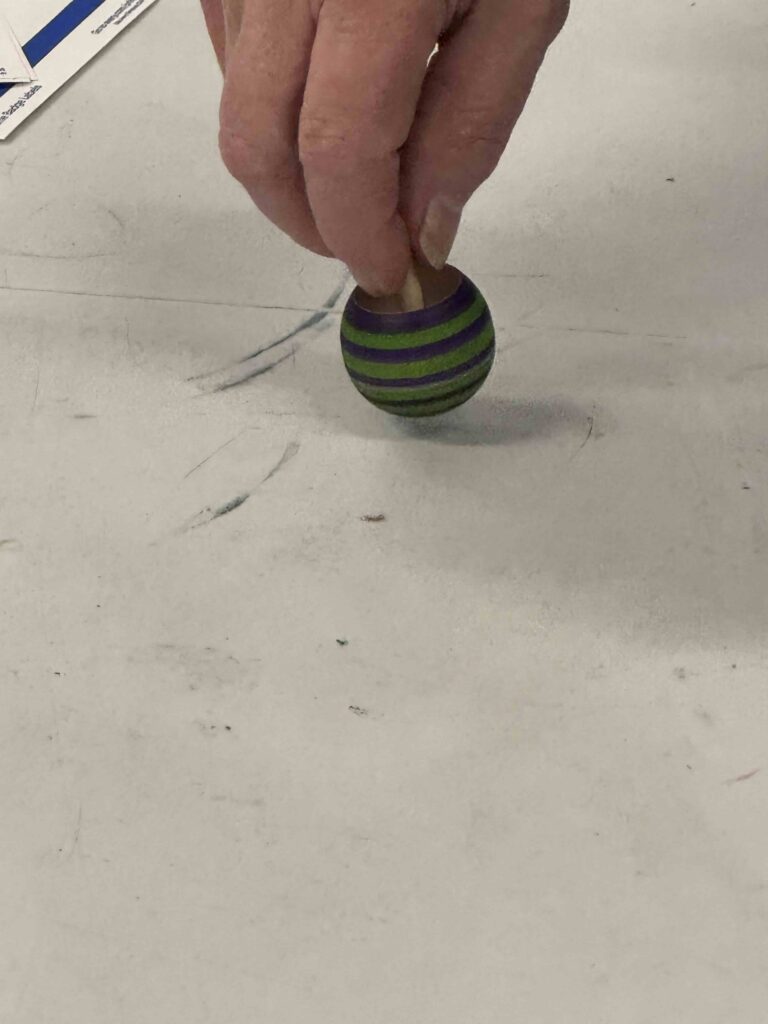

Our meeting included a demonstration on making tops, show & tell and wood auction

Dan’s Top Demonstration

Demonstration began with Dan suggesting that it is important to pick the correct style of top to make a good spinner. Some examples of poor design included: stem too thick; top to tall for diameter; disk (body of the top) too thin—the body should have significant mass to it. Ideal shape of the disk is wheel shaped. Remember the top should be large enough that it does not fall through the center of a toilet paper roll.

Dan used a parting tool and a spindle gouge to turn a top. The point of the disk should not be too sharp as it would be a puncture hazard. The stem should be about the width of a finger and 1/8 inch in diameter. Dan tapered both sides of the disk with the spindle gouge and shaped the stem with the parting tool.

Using Sharpies, Dan decorated the top and bottom of the disk. Ken remarked that at Black Moshannon, some of the kids liked the decorated tops, while others preferred to color the tops themselves. Club members were encouraged to turn their own tops over the next month and bring tops to the October meeting so the tops can be distributed to kids who come to the Reeds Gap State Park Fest demonstration, October 11, 2025 11:00-3:00.

Show & Tell

Our May meeting included an ornament presentation and show & tell.

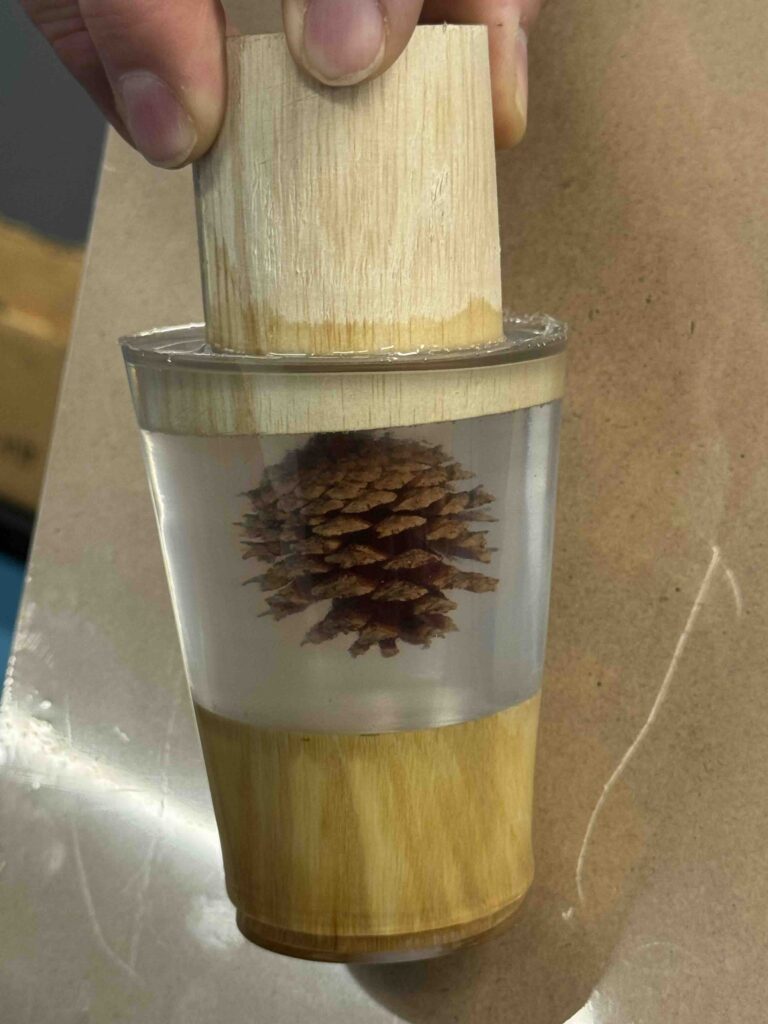

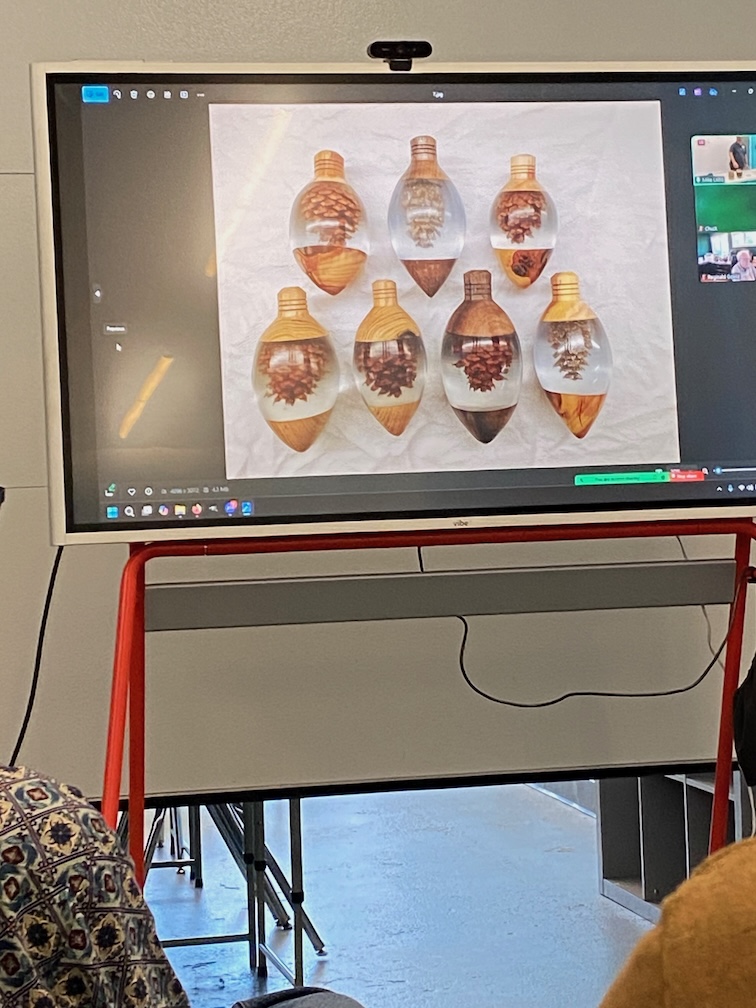

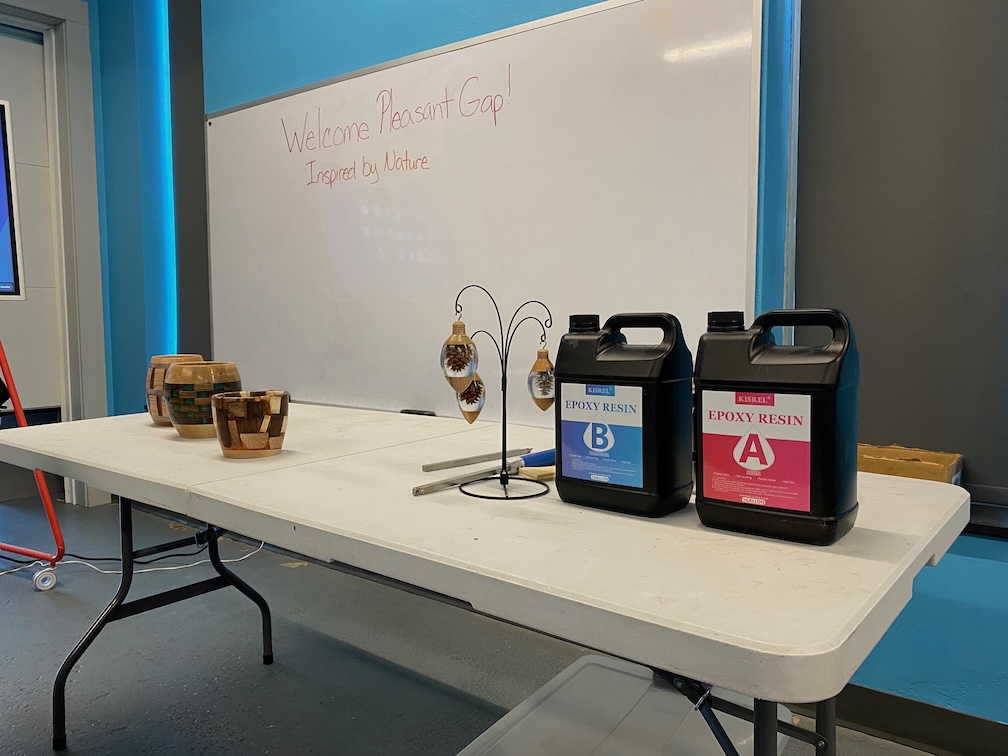

Gib Corl presented how he made Christmas ornament “bulbs” using pine cones and epoxy.

He showed an ornament with a small hemlock cone, but other center pieces can be used. The cone is hot glued to a blank and another blank is hot glued to the bottom of a plastic cup. The cone is suspended over the cup with a jig he has fabricated and after all the parts are in alignment, he pours the epoxy mix into the cup. He uses a 5 gallon pressure pot @ 60psi to compress any bubbles in the pour and waits about 48 hrs before removing the item. The cured assembly is then put in the lathe and turned to the desired shape, lacquered, and sanded up to 400 grit.

Show & Tell

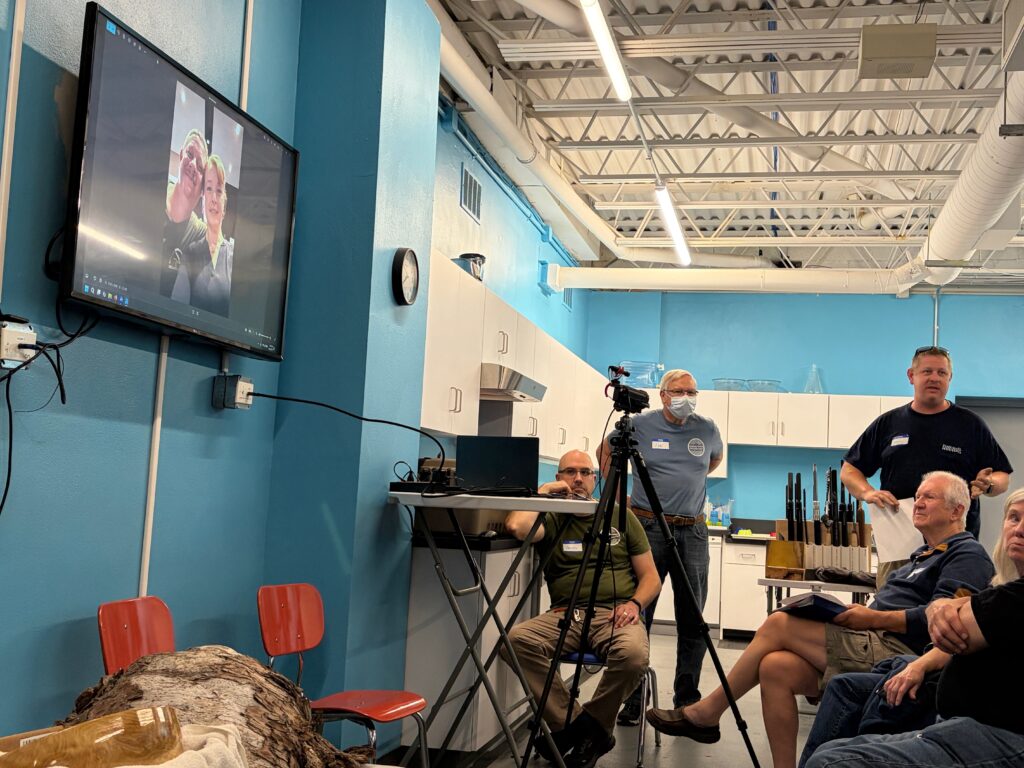

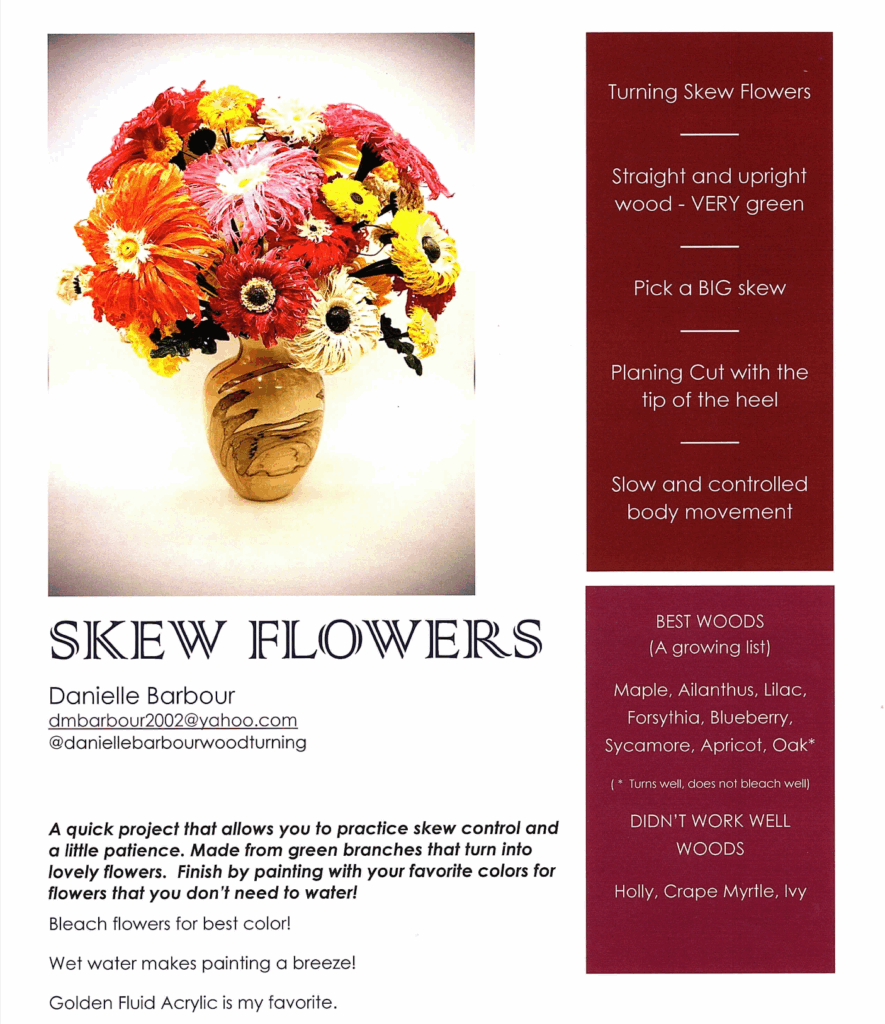

The Nittany Valley Woodturners welcomed Danielle Barbour, an accomplished woodturner featured in the American Association of Woodturners magazine. She demonstrated flower turning, shared her work, and discussed Women in Turning.

Danielle Barbour began turning in 2016. She passed out a handout that described her skew flowers. Her real job is emergency room nurse practitioner and turning helps her cope with that stress. She took lessons in bowl and hollow forms from David Ellsworth. She mostly uses a skew to shave a piece of wood, forming petals of a flower, Her flowers range in diameter from about an inch to 10 inches. She uses very green wood (recently cut or pruned in the spring), and many different species of wood. The blanks should be straight, with the pith centered, and free of knots and bark inclusions.

Danielle starts with the blank mounted between centers (cone live center, drive center held by the chuck jaws—steb center or cone) Using a roughing gouge she removed the bark and the cadmium layer and formed a tenon on one end. She then removed the blank and the drive center, remounting the blank with the pin jaws of the chuck and the live center cone. She keeps the tail stock close with the spindle as short as possible to reduce vibration of the blank.

Using a planing cut with her skew (1.5 inch skew with 50 degree included angle) she uses a planing cut to shave the tail stock end of the blank towards the head stock, pushing up the shaved wood into petals. She uses the tip of the heal of the skew to make very light planing cuts. The tool rest is angled away from the head stock so that the tool rest does not hit the petals.

She parts the flower off the blank with a “V” cut. Using Zinzer’s two-part wood bleach, she whitens the flowers to prepare them for paint. She uses Golden Fluid Acrylic with “wet” water to paint the flowers after they have completely dried from the bleaching. She attaches the flowers to aluminum or copper rods that are wrapped in a green tape—tape rather than painted rods as the paint would crack when the rods were bent during arranging the flowers for display.

Danielle explained how the Women in Turning (WIT) concept is practiced at her club. She showed the October 2024 issue of the America Association of Woodturners (AAW) magazine, featuring her flowers and several wood piercing bowls and ornaments. She also encouraged people to attend the Mid Atlantic Woodturning Symposium,

Demonstration

Dan demonstrated how to make Gnomes.

Dan provided notes so anyone can make a gnome like he does:

Show & Tell

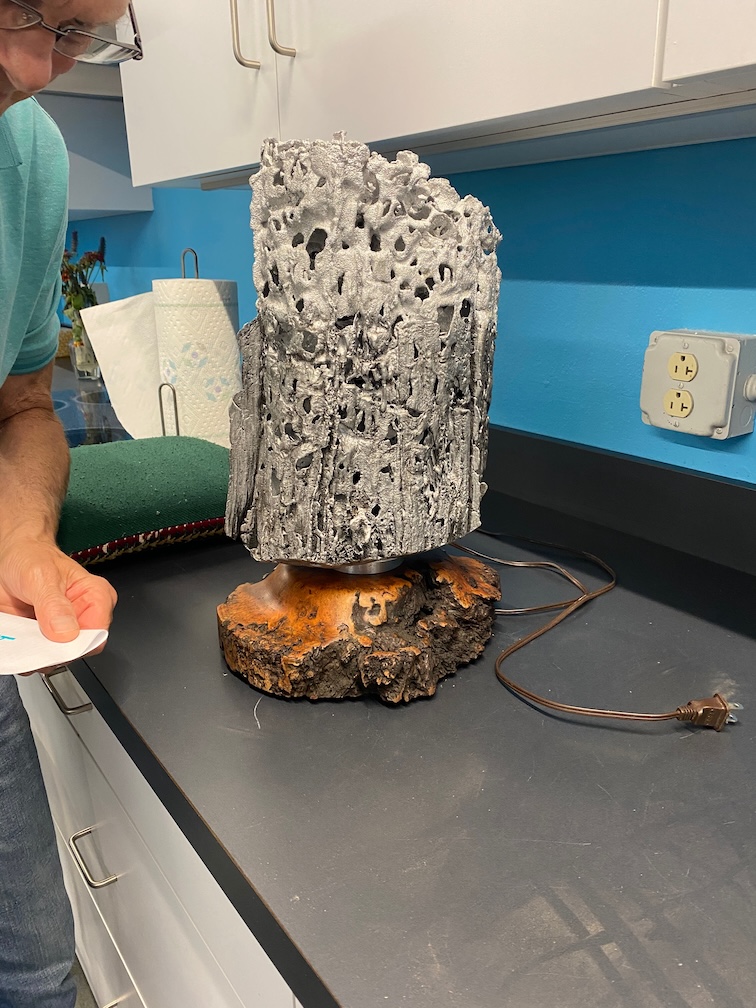

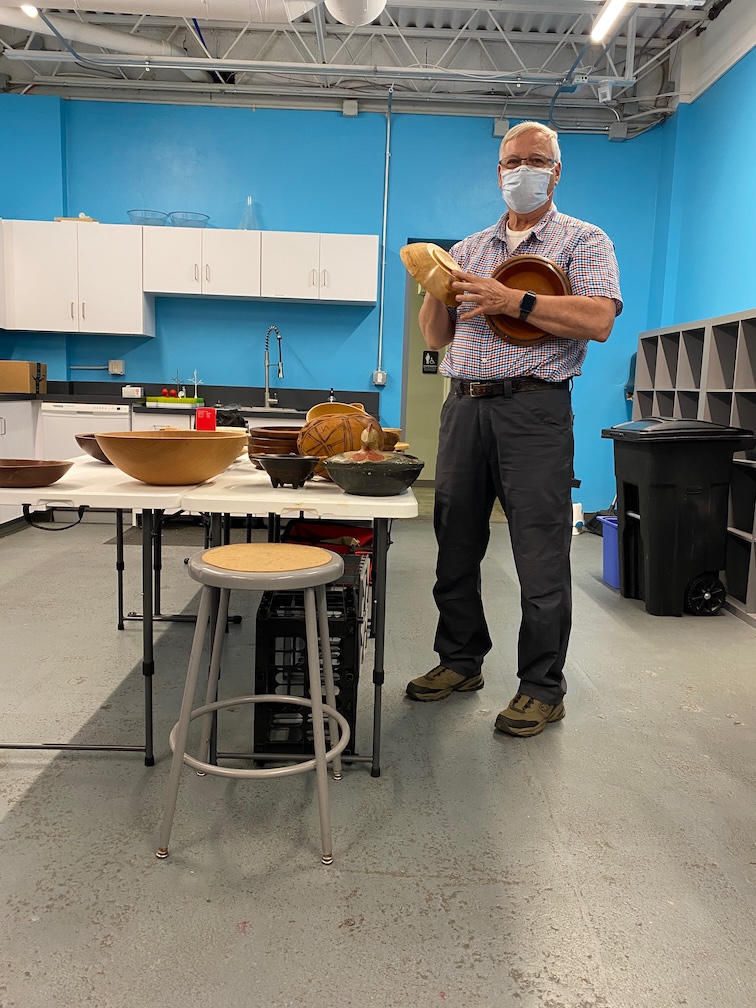

We had a normal show and tell where we saw members amazing work

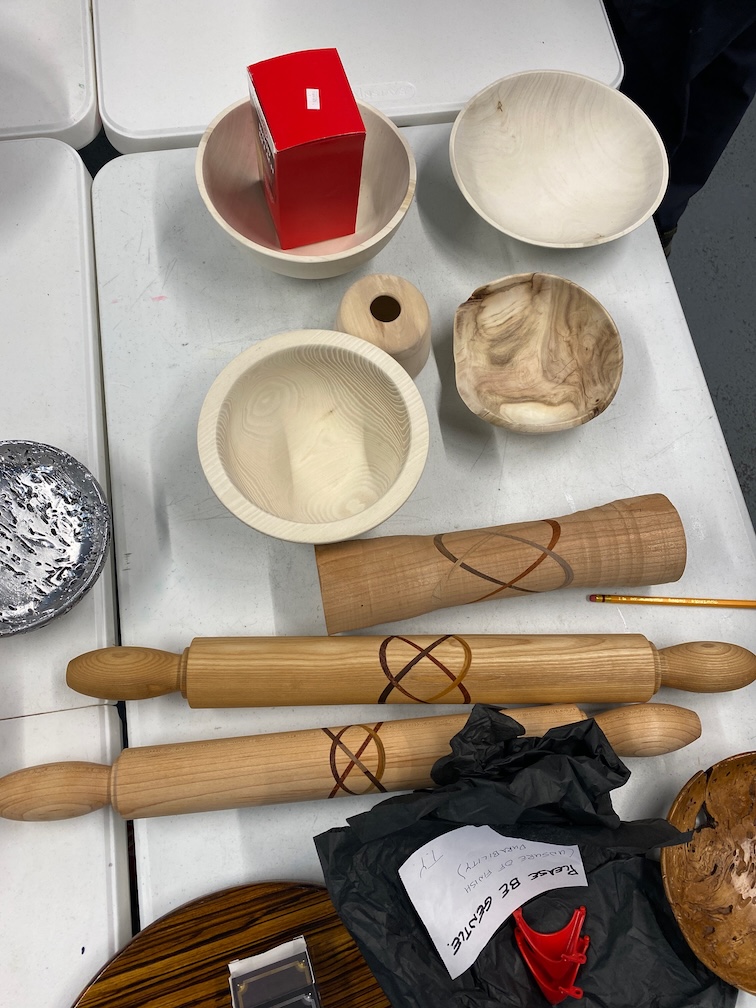

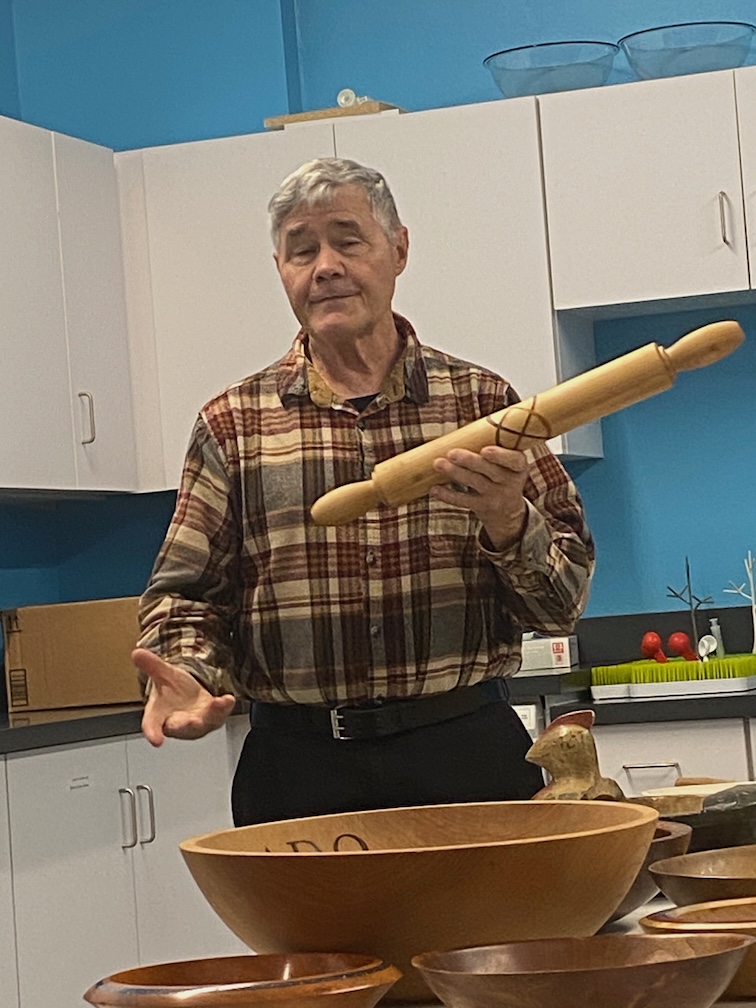

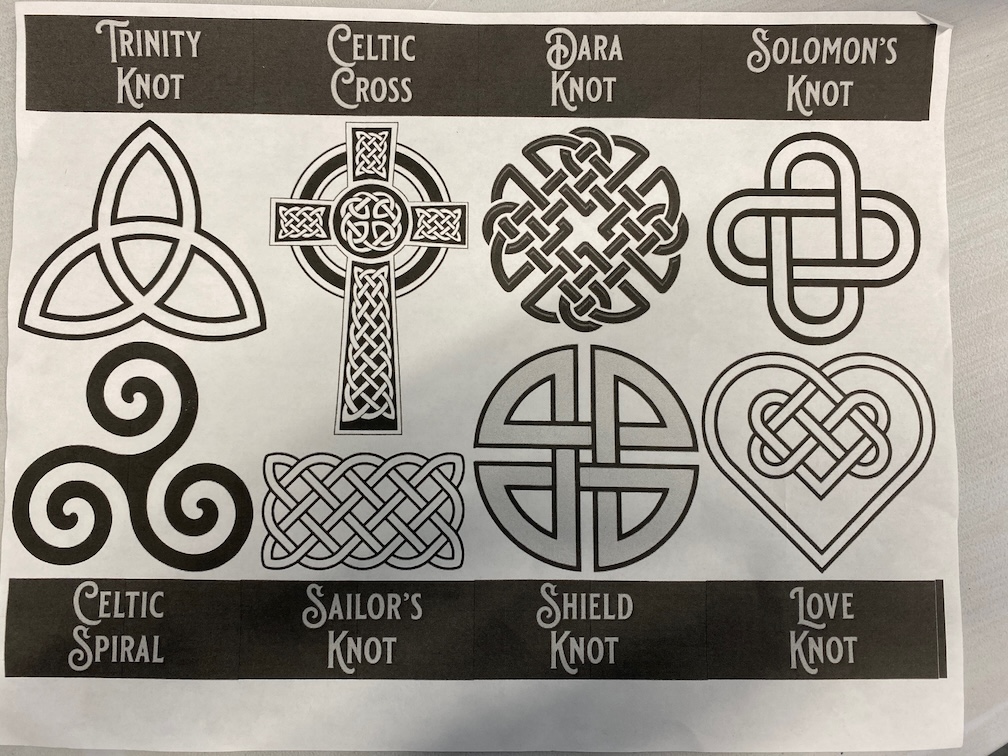

Paul Demmert shared how to make a Celtic Knot rolling pin. A Celtic knot is an infinite loop type pattern which makes an impressive decoration on a rolling pin. But first we had our regular show and tell where several people showed us what they’ve been making lately, from sculptures to grinders to chips and dip bowl.

Below are examples of various Celtic knots.

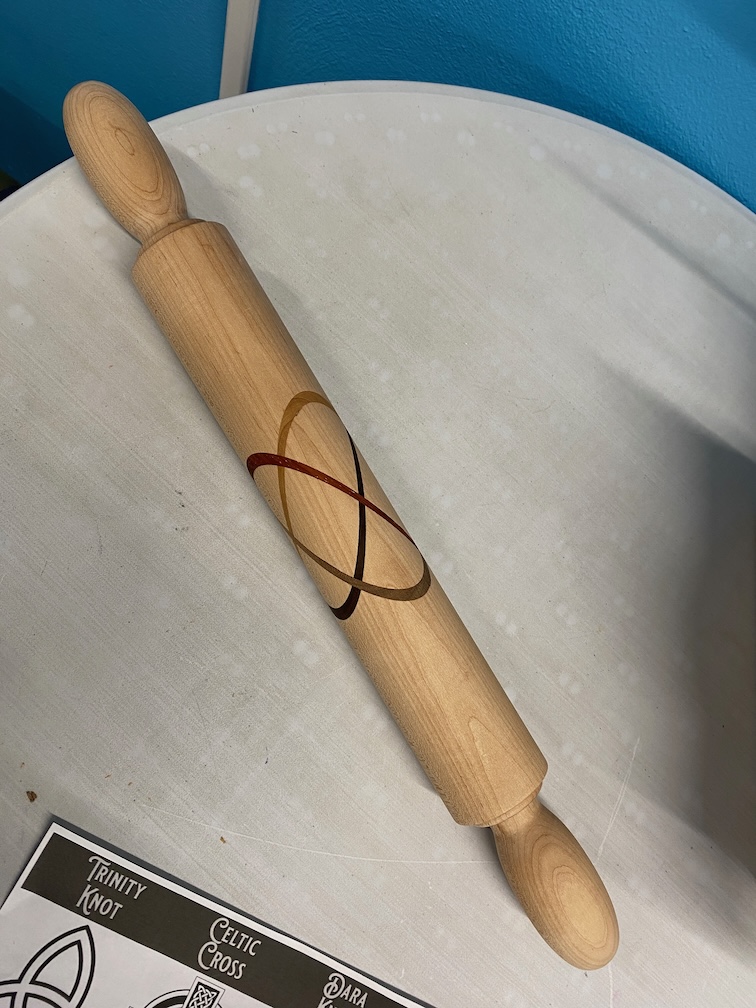

Below is an example of how to layout the cuts made in the blank before turning. You must make deep cuts just 1/8″ short of going through to hold it together until glued. Place a different colored 1/8″ thick wood blank in each slot, cut and glue one at a time.

Some other tips he shared:

Due to the demo lathe’s size limits Paul used smaller pieces to show how it’s done.

Look at this beautiful final product, when done on a full sized lathe.

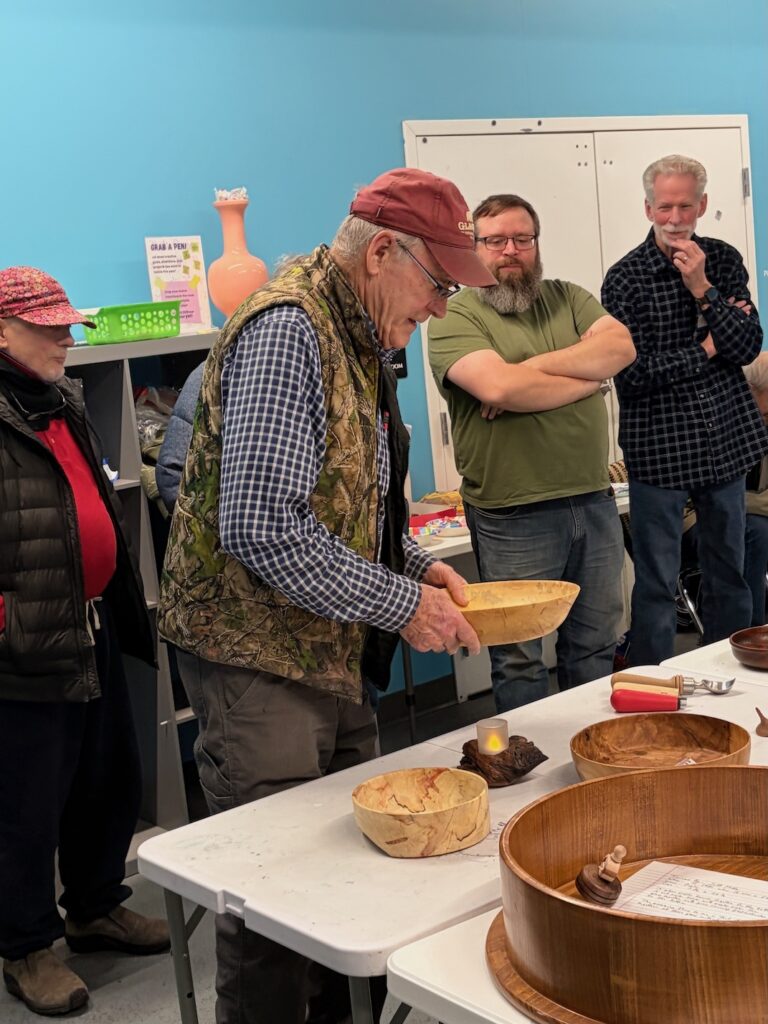

Our first meeting after the summer break was a time to reconnect and learn what everyone made over the summer, so we had a larger than normal show and tell session as well as a great wood auction.